Introduction

The thermal performance of wall assemblies plays a crucial role in the quest for more thermally efficient buildings. As the push toward sustainability intensifies, architects and builders prioritize reducing energy consumption through improved building design and materials. A high-performance continuous insulation system is essential for minimizing energy transfer, maintaining occupant comfort, reducing demand for heating and cooling, and enhancing the overall sustainability of the building.

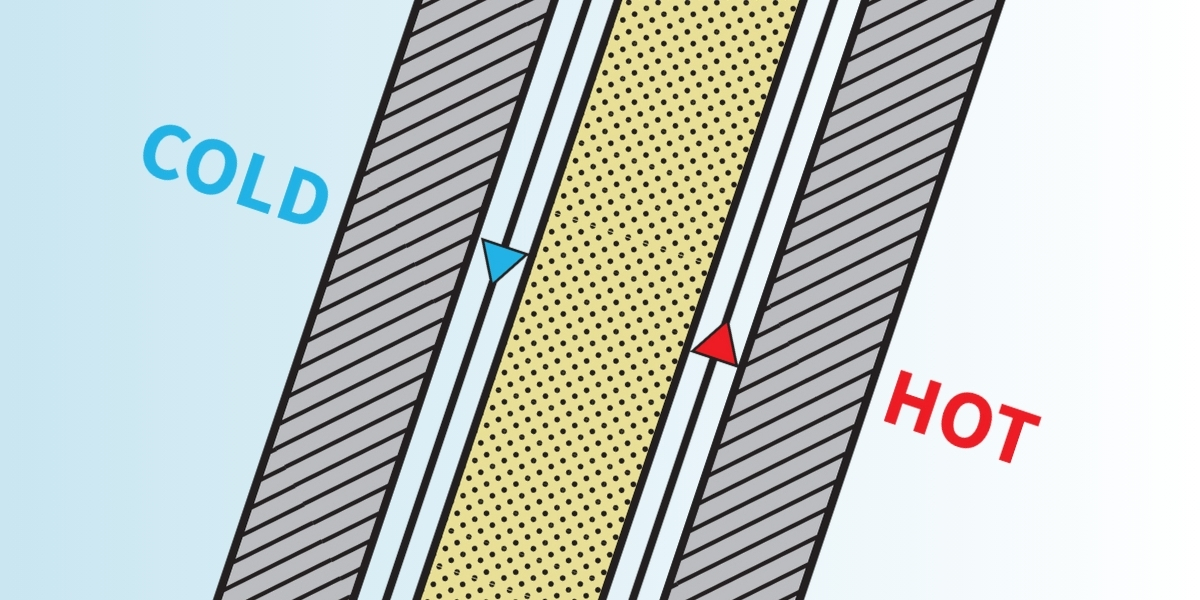

A comprehensive three-step approach focusing on selecting and using high-performance insulation, eliminating thermal bridging, and preventing thermal bypasses is essential to achieve these goals. The subsequent sections will explain each of the three steps.

Image 1: Three-step approach to highly thermally efficient continuous insulation systems

1. Specify High-Performance Insulation

Insulation is the primary component that reduces energy transfer through the building envelope. High-performance insulation materials are characterized by low thermal conductivity, moisture resistance, and air permeability.

Some examples of these materials include polyisocyanurate (polyiso), extruded polystyrene (XPS), stone wool, and aerogel. These insulation materials provide superior thermal resistance per unit thickness, allowing for thinner wall profiles while maintaining high R-values. Additionally, their moisture-resistant properties help prevent thermal performance degradation due to water intrusion or condensation.

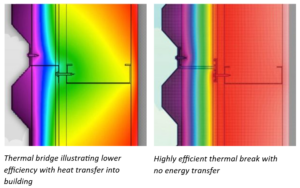

2. Eliminate Thermal Bridges

Thermal bridging occurs when highly conductive materials, such as structural elements or metal fasteners, bypass the insulation layer and create a path for energy transfer. This can significantly reduce the overall thermal performance of the wall assembly. Several strategies can be employed to minimize thermal bridging. Continuous insulation, applied uniformly across the exterior wall surface, helps to reduce the impact of thermal bridges caused by studs or other structural components.

Thermally broken structural profiles, fasteners, and supports, such as low-conductivity clips or spacers, can attach the insulation and cladding while minimizing energy transfer. Furthermore, insulated window and door frames can prevent thermal bridging at these critical junctions.

Image 2: Example of a thermal bridge vs. thermal break

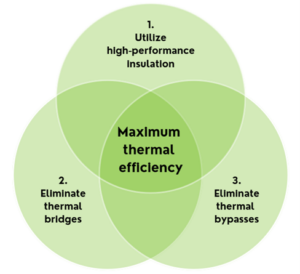

3. Eliminate Thermal Bypasses

Thermal bypasses refer to the unintended movement of energy through gaps, cracks, or voids in the wall assembly. Design flaws, material inconsistencies/tolerances, or improper installation can cause these bypasses.

Eliminating gaps behind insulation panels and cracks between adjacent insulation panels are crucial quality control measures necessary for preventing thermal bypass and maintaining the specified R-value. Proper design is required to prevent air leakage and moisture intrusion.

Insulation panels custom-profiled in a factory to the exact specifications of the selected sub-framing system can have up to double the thermal efficiency of a pairing with material inconsistencies/tolerances that generate gaps, cracks, or voids. Finally, thorough air sealing and weatherization techniques, such as spray foam or caulking at penetrations and junctions, are necessary to further reduce the risk of thermal bypasses.

Video 3: An example of thermal bypasses, where air flows around and through insulation.

Conclusion

Creating a highly thermally efficient continuous insulation system requires a holistic approach. This approach includes the careful selection of insulation and the elimination of both thermal bridging and thermal bypasses. By strategically integrating high-performance insulation materials, designers and builders can enhance thermal performance. Additionally, implementing measures to eliminate thermal bridges and bypasses allows for the construction of wall assemblies with superior thermal efficiency.

This comprehensive three-step approach enhances the building’s energy efficiency. It also contributes to significant energy savings, reduced environmental impact, and improved comfort for occupants. As the construction industry continues to evolve toward more sustainable practices, the role of innovative building products and materials becomes increasingly crucial. These steps are pivotal in driving the industry forward, enabling more effective and sustainable building practices. Understanding and implementing these key elements are essential for achieving high-performance building enclosures, thereby paving the way for a more sustainable future.

SMARTci® Building Enclosure Systems

SMARTci building enclosure systems exemplify innovative building technology, meticulously engineered to address the critical aspects of thermal efficiency in wall assemblies. These systems integrate high-performance, custom-profiled insulation panels with GreenGirt CMHᵀᴹ Z-girts and necessary accessories to achieve 92-98% thermal efficiency, eliminate thermal bypass, and provide the highest R-value available. The SMARTci system is engineered to minimize energy transfer across the building envelope by employing advanced materials and a comprehensive design approach. This holistic strategy enhances the thermal efficiency of buildings and promotes significant energy savings and improved interior comfort.

The innovation of SMARTci systems is evident in their components and assembly methods. Engineered with thermally broken Z-girts made from a composite metal hybrid material, these systems are designed to eliminate energy loss through structural elements while also eliminating thermal bridges. Furthermore, SMARTci’s solutions incorporate precisely engineered insulation panels and components. These panels compression seal on all horizontal and vertical axes, eliminating gaps, cracks, and voids, and removing any potential thermal bypasses. SMARTci is leading the construction industry toward more sustainable and thermally efficient practices with its engineered solutions. These innovations meet the growing demand for environmentally responsible building options.

To learn more about the SMARTci building enclosure system, visit GreenGirt.com. You can also explore additional high thermal efficiency solutions by Advanced Architectural Products.

To learn more about maintaining the efficiency and integrity of your building structures, be sure to read our article “Understanding and Addressing Thermal Bypasses in Building Enclosures – Gaps, Cracks, and Air Channels Inside Your Building Enclosure.”

© 2024 Advanced Architectural Products