As anyone in the construction industry knows, thermal expansion is a major factor to consider when working with any kind of building material. In fact, just about every type of material used in construction is affected by expansion to some degree. That’s why it’s so important for architects and engineers to understand how different materials will respond to temperature change.

With that knowledge, architects and designers can account for thermal expansion in their designs and ensure that structures are safe and stable. So, let’s take a closer look at how it works and how it affects common building materials.

What is thermal expansion, and how does it happen?

Thermal expansion is defined as a physical phenomenon in which materials expand when heated. As thermal energy increases, the bonds between atoms and molecules become more active, which causes them to repel each other and spread farther apart, which can cause the building material’s initial length, width, and original volume to change. This results in materials expanding, although the amount of expansion varies greatly depending on the material and its other properties.

Such an understanding of thermal expansion is important for all areas involving construction, as different materials have different expansion rates that need to be taken into account when constructing buildings. Furthermore, expansion can cause severe damage if left unchecked due to certain building materials requiring an accommodation to prevent thermal stress from expansion.

How is thermal expansion calculated?

You can calculate expansion in various ways, with the most common being the linear thermal expansion coefficient. This is the ratio between the change in length and the original length per degree Celsius (°C). The units are typically m/m °C or cm³/cm³ °C, depending on whether you’re calculating linear or volumetric expansion.

As mentioned, just about every type of building material can be affected by thermal expansion. However, some materials have larger expansion coefficients than others. Different materials have different expansion coefficients, and these must be taken into account for a successful construction project. Knowing how thermal expansion affects materials can help architects and engineers design structures that are safe and stable in changing temperatures.

How does thermal expansion affect building materials differently?

Thermal expansion impacts building materials, but the effects can vary greatly depending on the specific material. Generally, building materials that expand rapidly when exposed to an increased temperature – such as glass and metal – are susceptible to more dramatic changes caused by expansion. A material’s coefficient of thermal expansion can result in a change in the length or volumetric coefficient of the material, and this must be taken into account when designing a structure.

On the other hand, building materials composed of aggregates – such as concrete and stone – may not shrink or expand significantly when heated or cooled. However, building materials in these categories will still experience stresses due to the unequal distribution of heat throughout their components, which can weaken structures over time. Therefore, builders need to take into consideration the effects of thermal expansion when determining building material selections for a project.

Let’s take a look at how various building materials are affected by the phenomenon.

Metal

Thermal Expansion in Metals

Metal is one of the materials that are most prone to thermal expansion. When exposed to high temperatures, metals expand at a much faster rate than other building materials such as wood and stone. These expansions can cause thermal stress on the surrounding material and weaken structural connections if not properly accounted for. This can happen both in short-term exposures, such as the metal expanding due to high temperatures in summer or in long-term exposures such as metal being exposed to fire.

Impact on Structural Connections

In addition, the volumetric expansion and linear expansion of metal can cause connection failures due to increased stresses on the surrounding material. For instance, if bolts holding a structural beam together expand differently in various areas due to thermal expansion (e.g., bolts at different heights expanding differently), the connection between them could fail and cause structural damage. For this reason, builders must consider the effects of expansion and volumetric expansion on metal when designing a building’s infrastructure.

Risk of Corrosion Due to Expansion

Finally, the thermal expansion of metal can also lead to corrosion if moisture is present in the material. If a surface expands due to heat and then contracts, this could cause cracks in the metal, which can then create areas for moisture to accumulate and lead to corrosion. Builders need to ensure that their designs account for the expansion of metal if they want to ensure that their structures are safe and reliable over time.

Designing for Thermal Expansion in Metals

Overall, thermal expansion and linear expansion have a great effect on metal and can cause significant damage to structures if not taken into consideration during the building process. Builders should ensure that they factor in the effects of expansion when planning for metal elements, such as using proper insulation materials and taking into account different rates of thermal expansion at different heights and locations. This will help ensure that the structure remains safe and reliable over time.

Wood

The thermal expansion also commonly occurs in wood, which generally expands along its grain as it heats up. Wood is a popular material for construction projects; however, understanding how expansion affects it can be beneficial in ensuring structural integrity over time.

Wood is a hygroscopic material, meaning it absorbs and desorbs moisture from the atmosphere. This can cause wood to swell and shrink depending on the humidity in the air, which affects thermal expansion as well. With a rise in temperature, wood expands along its grain further, resulting in a greater degree of contraction when temperatures drop.

Wood is also prone to shrinking and expanding at different rates depending on the type of wood used and its grain orientation. This can cause the material to warp or crack over time, making it important for builders to factor in thermal expansion when designing wooden structures. Ultimately, builders should take into consideration the type of wood used or the combination of woods with different expansion characteristics.

It is important to take into consideration thermal expansion when working with this material to ensure structural integrity over time. By doing so, builders can create wooden structures that are safe, reliable, and capable of standing up to the test of time.

Concrete

Concrete is a popular building material due to its durability and versatility. It can be used for a variety of applications, from sidewalks to bridges. However, it is important to understand thermal expansion when working with this material to ensure long-term structural integrity.

When exposed to heat or cold, concrete will expand or contract similarly to other materials. The degree of expansion or contraction depends on several factors, including the type of cement used, the aggregate size and composition, the water-cement ratio, and the age of the concrete.

Concrete generally resists thermal expansion better than other materials; however, designers should still consider it when working with concrete components. To minimize the effects of expansion on concrete, designers can consider using different types of cement, aggregates, and water-cement ratios in their design. Additionally, the use of insulation can further reduce expansion in concrete components.

Overall, concrete is an excellent building material due to its versatility. By using different types of cement, aggregates, and water-cement ratios as well as considering the use of insulation, designers can create concrete components that are safe, reliable, and capable of standing up to the test of time.

Phenolic (Glass Reinforced):

Engineers and builders commonly use phenolic (glass-reinforced) composite material for its low weight, high strength, and excellent thermal properties. Despite these advantages, it still experiences thermal expansion when exposed to different temperatures. Understanding how this material responds to it can help designers create structures that are safe and reliable over time.

The resin used in the construction of glass-reinforced phenolic largely determines its expansion. Different resins have different coefficients of thermal expansion, with some exhibiting greater rates than others. Additionally, glass fibers often reinforce glass-reinforced phenolic panels, contributing to their overall coefficient of thermal expansion. The orientation and content of these glass fibers will affect the overall rate at which the material expands when exposed to a change in temperature.

Glass-reinforced phenolic is also sensitive to moisture, meaning that even small changes in humidity can cause it to expand or contract slightly. As a result, designers must be mindful of their environment and factor in any possible moisture fluctuations when designing and constructing with this material.

Overall, glass-reinforced phenolic is a versatile material that can be used in many applications. However, designers must consider its coefficient of thermal expansion when designing and constructing with this material to ensure safe and reliable structures over time. By taking into account the type of resin used as well as any potential moisture fluctuations, engineers can create structures that are capable of standing up to the test of time.

GreenGirt CMH™

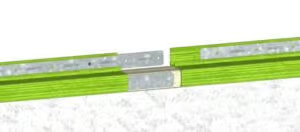

Steel inserts extend min. 3” with 1/16” to 3/16” gap for thermal expansion

Innovative Design for Thermal Expansion and Energy Efficiency

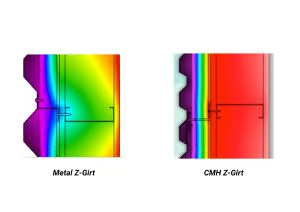

GreenGirt CMH™ is an innovative Z-girt, comprised of a composite metal hybrid material, designed to reduce thermal expansion and the transfer of energy while providing a durable, reliable continuous insulation and building enclosure sub-framing for construction projects. It consists of a composite fiberglass Z-profile with steel fastener retention plates in each flange, resulting in a lightweight but structurally-sound material that minimizes the effects of expansion. With the use of steel and composite fiberglass, GreenGirt CMH will be more resistant to expansion than other common materials.

Enhanced Structural Stability and Energy Control

The steel fastener retention plates in each flange provide a secure attachment surface, ensuring structural stability over time. The composite metal hybrid material also has a low thermal conductivity, meaning it eliminates thermal bridging and the transfer of energy of moisture from one area to another. This feature is beneficial for controlling interior environments since it can help maintain a consistent temperature throughout a building. This feature also has a positive effect on the overall health of a building.

Interlocking Connection System for Stability in Extreme Conditions

In addition, the steel component of GreenGirt CMH sub-framing features an interlocking connection system that absorbs movement with expansion joints and helps stabilize the structure. To accommodate the expansion that does occur, Advanced Architectural Products recommends a 1/16″ to 3/16″ gap between GreenGirt CMH Z-girt pieces. With this consideration, GreenGirt CMH sub-framing is an ideal solution for buildings located in areas prone to low and high temperatures. It also helps to ensure that buildings keep their structural integrity even with long-term exposure to the elements.

A Reliable Solution for Long-Term Durability

Overall, GreenGirt CMH sub-framing is an excellent building component designed with thermal expansion and stability in mind. Its lightweight nature and low thermal conductivity make it ideal for use in a variety of building envelope applications, while its unique interlocking connection system helps with structural stabilization. GreenGirt CMH continuous insulation and SMARTci building enclosure systems, both utilizing GreenGirt CMH sub-framing, are excellent options for architects and engineers looking to create safe, reliable, and durable structures that stand up to the elements.

Thermal performance comparison of metal versus CMH Z-girts.

Why is thermal expansion something that needs to be considered in construction projects?

Thermal expansion is an immensely important factor to consider during construction projects. After completing the project, the materials in the structure must withstand and adapt to expansion from temperature fluctuations.

If thermal changes go unchecked, a building can experience serious structural damage from the stress caused by the natural expansion or contraction of materials like wood, concrete, and metal. More importantly, these issues create large safety risks for people using a building, which is why projects across many industries must consider expansion when carrying out construction.

To view values for coefficients of thermal expansion of common building materials, see our report here.

What are some ways to account for thermal expansion in building components during the construction process?

When constructing a building, it is important to consider how the thermal expansion of materials can affect the structure long term. Depending on the material, it can have adverse effects on the structural integrity of a building if not accounted for during the construction process. Builders should design with allowances for expansion to reduce structural weakening caused by temperature changes over time.

Furthermore, several techniques, such as utilizing different materials for other components within the building, can help even out temperature changes made to some parts of a structure. Taking these precautions during construction can alleviate many potential problems associated with the thermal expansion of commonly used construction materials.

Why is it Important to Account for Thermal Expansion in Your Building Envelope?

Thermal expansion is a critical consideration when installing continuous insulation or building enclosure systems, as it directly impacts the structure’s integrity and long-term performance. Temperature fluctuations cause materials to expand and contract, which can place stress on the insulation components. If not properly accounted for, this can lead to warping, cracking, and other forms of structural damage.

By addressing thermal expansion, you ensure that your building envelope system can withstand these temperature changes while maintaining optimal performance. With the use of GreenGirt CMH Z-girts, you benefit from superior thermal performance, durability, and structural strength. GreenGirt CMH Z-girts offer similar or better expansion coefficients than other sub-framing materials and support heavy cladding and material loads, making them ideal for various construction projects.

GreenGirt CMH™ Continuous Insulation and SMARTci® Building Enclosure Systems

As the industry’s leading composite metal hybrid continuous insulation and building enclosure sub-framing solution, GreenGirt CMH Z-girts deliver exceptional performance. It provides unmatched thermal efficiency and structural performance in modern building designs.

Ask A2P’s Expert Engineers About Thermal Movement & Attachment Details

Our engineers are here to help you design with the best possible GreenGirt and SMARTci configuration for your next project so that thermal expansion/contraction doesn’t turn into stress, noise, or callbacks.

Related Resources:

Read “Maximum Service Temperature: Why Temperature Limits Matter for Material Behavior”

A2P’s Wall, Window, and Roof Solutions to Accommodate Thermal Movement

–

–

Frequently Asked Questions

How do I calculate thermal expansion for a building material?

You can calculate it using the linear thermal expansion coefficient: the ratio between change in length and original length per degree Celsius (°C).

Why does metal framing cause problems with thermal expansion?

Metal framing causes problems with thermal expansion because metal expands faster than materials like wood and stone when temperatures rise, which can create thermal stress and weaken structural connections if it isn’t accounted for. Uneven expansion (like bolts expanding differently at different heights) can contribute to connection failures, and expansion/contraction cycles can create cracks that trap moisture, increasing corrosion risk.

What gap should I leave between GreenGirt CMH Z-girt pieces for thermal expansion?

We recommend leaving a 1/16″ to 3/16″ gap between GreenGirt CMH Z-girt pieces to accommodate thermal expansion. Also, GreenGirt CMH uses an interlocking connection designed to absorb movement with expansion joints.