Introduction

Screw pull-out, or the phenomenon where a screw is extracted from its bind due to stress or strain, can significantly compromise the integrity of fiber-reinforced polymer (FRP) materials in construction. Although FRP’s inherent characteristics, like its high strength-to-weight ratio, make it a preferred choice in challenging construction scenarios, the propensity for screw pull-out is a concern that cannot be overlooked.

It particularly becomes an issue when these materials are subjected to heavy loads or adverse environmental conditions, where the resistance to such forces is critical in preserving the structural integrity. The following sections will delve deeper into the technical aspects of screw pull-out in FRP materials, discussing how it occurs, its implications, and potential strategies to mitigate its effects. We aim to provide a comprehensive understanding of this vital aspect, enabling architects and construction professionals to consider these factors when choosing FRP for their projects.

Understanding Screw Pull-Out in FRP Materials

Screw pull-out, or the ability of a fastener to resist being pulled out of a material it’s been inserted into, is a deciding factor in the structural integrity and durability of buildings. When it comes to FRP materials, the lack of proper attention to screw pull-out can lead to compromised stability and premature failure of the structure.

Causes and Implications of Screw Pull-Out in FRP Materials

Screw pull-out in FRP materials can occur due to several reasons. A primary cause is the inappropriate choice of screws, wherein their design or size is not compatible with the thickness or density of the FRP material. Moreover, incorrect installation of screws, such as over-tightening, can lead to the deformation of the FRP material, promoting pull-out.

When screw pull-out occurs, it undermines the load-bearing capacity of the FRP structure. The connection points become weak, leading to a reduction in the overall strength and stability of the construction. In severe cases, it can lead to catastrophic structural failures, posing safety risks and necessitating costly repairs.

To mitigate the screw pull-out, it is imperative to select screws of appropriate design and size, considering the specifications of the FRP material. Moreover, the inclusion of supplementary support elements, such as metal backing plates, is required to resist screw pull-out, ensuring the longevity and reliability of FRP constructions in diverse conditions. In the upcoming section, we will explore the role and implementation of these mitigation strategies in depth.

The Impact of Screw Installation on FRP Strength

When installing screws into FRP materials, a concerning phenomenon occurs. The screw teeth, while penetrating the material, act similarly to a pair of scissors, severing the fiberglass threads integral to the FRP.¹ This analogy explains how the installation process can unwittingly weaken the FRP material.

Fiberglass threads in FRP materials provide much-needed strength and durability. During the screw installation, the rotation of the screw and the sharpness of the screw threads cut through these fibers, creating a localized area of weakness in the FRP material. This interruption to the continuous fiber strand weakens the load-bearing capacity and overall durability of the FRP at the point of the screw’s insertion.

The more these threads cut through the fiberglass threads, the more the FRP is weakened. This weakening can contribute significantly to the likelihood of screw pull-out occurring under stress or strain.

The Necessity of Steel or a Backer Plate in Preventing Fastener Pull-Out in FRP

After careful examination of the causes and implications of screw pull-out in FRP materials and considering the various mitigation strategies, it becomes decidedly clear that the use of steel or a backer plate is crucial to prevent such occurrences. The intrinsic properties of steel, including its superior tensile strength and rigidity, make it an ideal companion material to FRP. When steel is employed as a backer plate, it provides robust anchoring for the screws, significantly reducing the likelihood of screw pull-out.

This conclusion does not undermine the value of FRP materials in construction. Rather, it emphasizes the importance of employing complementary materials and techniques to bolster the structural integrity of FRP-based constructs. Ultimately, by incorporating steel or backer plates in the construction process, we can harness the potential of FRP materials, ensuring their longevity and reliability in various types of construction.

The Composite Metal Hybrid (CMHᵀᴹ) Solution

In response to the challenge posed by screw pull-out in FRP materials, Advanced Architectural Products has introduced GreenGirt® CMHᵀᴹ as a superior alternative to sub-framing materials. CMH incorporates steel with FRP, ensuring best-practice fastener retention and eliminating the risk of screw pull-out. By combining the high strength and corrosion resistance of FRP with the reliable fastener retention of steel, CMH offers a balanced solution by combining the benefits of FRP and steel that can withstand the demands of modern construction projects.

The Superiority of GreenGirt® Composite Metal Hybrid (CMHᵀᴹ)

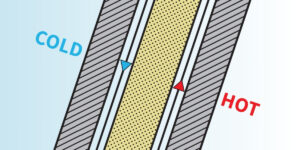

GreenGirt CMH boasts a revolutionary design that integrates the benefits of both FRP and steel. The front and back flanges, made with steel inserts, offer excellent fastener retention, while the core Z-profile, made from FRP, provides corrosion-resistance, lightweight, and high-strength characteristics. This unique composite ensures that CMH excels in areas where traditional FRP materials may fail, such as in screw retention.

The enhanced ability of screw retention reduces the possibility of screw pull-out, largely enhancing the durability of the construction. It also ensures that the integrity of the structure is maintained even under challenging environmental conditions or heavy loads. CMH’s superior performance in fastener retention helps avoid structural failures that often result from screw pull-out ensuring safer constructions and reducing the potential costs associated with repairs and renovations.

Beyond its technical superiority, the use of CMH also has economic implications. The reduced likelihood of screw pull-out means less trailing liability and fewer repairs and replacements over time, leading to lower maintenance costs. By offering a more reliable and durable solution, CMH can contribute to significant savings in the long term, making it a cost-effective choice for construction projects.

In summary, the GreenGirt® composite metal hybrid (CMHᵀᴹ) presents a forward-thinking response to the challenges associated with screw pull-out in FRP materials. Its design, which combines the advantages of FRP and steel, delivers a robust and reliable solution that raises the bar for construction materials.

Real-World Implications of Screw Pull-Out in FRP Materials

In real-world situations, the impact of screw pull-out in FRP materials without metal backer plates has far-reaching implications that extend beyond the immediate structural compromise. For example, in a commercial building, screw pull-out may not only lead to structural instability but could also pose potential safety risks.

In the case of infrastructure projects, such as bridges, screw pull-out could translate into critical failures, jeopardizing public safety. Consider a scenario where a pedestrian bridge constructed with FRP materials in structural components experiences screw pull-out. The weakening of the bridge structure could ultimately lead to collapse, endangering lives and necessitating expensive reconstruction efforts.

Similarly, in housing complexes, screw pull-out in FRP materials could lead to structural weaknesses, cracking, or deformation, compromising the longevity and safety of the buildings. The residents may face evacuation situations, and the complex might require extensive repair or even demolition, resulting in significant financial losses and displacement of families.

Cladding attachment provides another illustrative example of the implications of screw pull-out. Suppose you were to attach cladding directly into FRP without using a backer plate or a composite solution like CMH. The initial result may appear satisfactory. However, over time, the strain exerted on the screws from the weight of the cladding and the impact of environmental forces, such as wind, could lead to screw pull-out.

Screw pull-out in this context would compromise the secure attachment of the cladding, leading to potential detachment, which could pose a significant safety hazard. Loose or falling cladding pieces pose a direct risk to passersby and expose the underlying structure to climatic elements, accelerating wear and tear and increasing the demand for repair and maintenance.

In conclusion, the real-world implications of screw pull-out in FRP materials extend beyond the structure’s integrity, affecting financial resources, operational continuity, safety, and in some cases, environmental stability. Hence, the mitigation strategies discussed in this article and innovative solutions like GreenGirt composite metal hybrid (CMH) are crucial to tackle this issue effectively.

Empowering Architects with Knowledge

The objective of this article goes beyond simply sharing information; it is about fostering a deeper understanding and creating a strong knowledge base for architects in the field of FRP materials and their application. In the realm of architecture and construction, material selection has enormous implications on the durability, safety, and longevity of the structures.

Our campaign diligently addresses these concerns, delving into the intricacies of screw pull-out in FRP materials, its causes, implications, and suitable mitigation strategies. We strive to provide architects with the practical knowledge they need to tackle these issues and to make informed decisions that enhance the integrity of their projects.

The focus is not limited to the issue of screw pull-out alone. Through the article, we also shed light on groundbreaking solutions like GreenGirt CMH. The use of such hybrid materials opens up new avenues for construction, minimizing the challenges associated with traditional FRP materials and promising safer, more reliable structures.

In delivering these insights, we seek to empower architects and construction professionals with the tools they need to navigate the ever-evolving landscape of construction materials.

Join the Community

Ultimately, the goal is not just to disseminate information but to foster a community of well-informed and confident architects. We believe that by sharing knowledge and experiences, we can collectively raise the bar in the field of architecture and construction. Join us on this journey of learning and growth as we explore the technicalities of materials, their implications, and the solutions that ensure the longevity of our buildings.

Remember, the success of a structure lies in this foundation, and that foundation is built on the informed choices we make. Choose wisely, build powerfully.

The Future: Navigating the Landscape of Composite Materials

As we look into the future, it’s clear that the landscape of fiber-reinforced polymer (FRP) materials is far from static. The continuous evolution in the industry dictates that we must adapt, innovate, and consistently elevate our understanding of these materials and their applications. In this context, the role of a technical writer becomes even more vital, focusing on demystifying complex concepts and offering clear, actionable insights to architects and construction professionals.

However, as underscored in this article, the task of dealing with issues such as screw pull-out necessitates strategic thinking about the materials we use in construction. The incorporation of metal, particularly in the form of a backplate, in combination with FRP materials, emerges as an effective strategy. Its use facilitates a substantial increase in fastener retention, thereby mitigating the risk of screw pull-out. Therefore, it is essential for architects and construction professionals to understand and apply these insights, integrating metal backplates with FRP to ensure the structural integrity and longevity of their products.

Furthermore, the emergence of hybrid solutions like GreenGirt composite metal hybrid (CMH) signifies a major shift in the industry. By intelligently combining the benefits of FRP and steel, CMH offers a robust and reliable solution that can withstand the demands of modern construction projects. As such, an in-depth understanding of these hybrid materials and their applications will be integral to the future of construction.

We encourage architects and construction professionals to actively engage and collaborate on the topic of composite materials in construction. By sharing knowledge, experiences, and insights, we can collectively navigate the complex landscape of composite materials and their applications, ensuring a safer, more efficient, and sustainable future for the construction industry.

If you are interested in learning more about GreenGirt composite metal hybrid (CMH), GreenGirt CMH continuous insulation, or SMARTci building enclosure systems, please contact us today!

© 2023 Advanced Architectural Products

Sources:

¹ American Society of Civil Engineers (2022). Pull-out Behavior of Connections Using Self-Drilling Screws for Pultruded Fiber-Reinforced Polymer Composites in Construction. Journal of Composites for Construction. Volume 27, Issue 1. https://ascelibrary.org/doi/abs/10.1061/JCCOF2.CCENG-3949