Introduction

In the world of construction, there’s no room for error. The stability and safety of a structure hinge on meticulous planning and rigorous testing practices. Advanced Architectural Products’ (A2P) dedication to high standards of quality and safety is demonstrated through our comprehensive approach to mechanical, thermal, physical, and fire testing. These tests not only measure the strength and performance of building materials, but also serve as an assurance of reliability and longevity. We understand that maintaining structural integrity isn’t just about using top-quality materials—it’s also about ensuring those materials can withstand the forces they will encounter in real-world applications.

This article provides an overview of two mechanical testing practices integral to A2P’s informed product design: static structural testing and fastener testing. Whether you’re an architect, contractor, or anyone interested in the world of construction, join us as we explore the importance of comprehensive testing practices in ensuring the success of your construction projects.

Static Structural Testing

Static structural testing is a two-pronged approach that involves tensile and compression testing. These tests are not just crucial for maintaining our product integrity; they’re the lifeblood of our commitment to delivering reliable and resilient construction materials.

Tensile Testing: Pulling Apart the Facts

Tensile testing, also known as tension testing, gauges a material’s strength and behavior under tension. It’s a bit like a tug-of-war with the material you’re testing. The aim is to determine how much force it takes to pull the material apart. This information provides valuable insights in the material’s tensile strength, elasticity, and ductility.

The setup for tensile testing is straightforward yet precise. A specimen—often a cylindrical or flat piece—is placed in a machine where it’s pulled apart until it breaks. By measuring the force required to do this, we can understand the material’s inherent strength and how much it can stretch before breaking—critical factors in applications such as welding.

Tensile testing helps determine if a filler metal is suitable for a specific application and is often a vital part of procedure qualification records for welding codes. The results of tensile testing offer a comprehensive overview of a material’s strength, ductility, and other characteristics, enabling us to make informed decisions about its suitability for different applications.

For orthotropic materials like Fiber-Reinforced Polymer (FRP) – materials that do not have the same properties in all directions – it is important to test both lengthwise and crosswise and publish both properties.

Fastener Testing

The strength of a structure lies not just in its grand design, but also in the seemingly insignificant components that hold it together. At Advanced Architectural Products (A2P), we recognize the importance of these small yet mighty elements—fasteners.

Fastener pull-out and fastener torque are two critical elements that make up the backbone of fastener performance. Imagine forcibly removing a mechanical anchor, like a bolt or screw, from its hole. This process, known as fastener pull-out, can potentially cause damage. More importantly, this term denotes the force required to extract a fastener, reflecting its holding strength—a key determinant of structural integrity and safety.

On the flip side, fastener torque refers to the tightening force applied to secure a fastener in place. Striking the right balance is crucial. Applying too much torque, and you risk stripping threads or deforming fasteners. Apply too little, and you may face the danger of loose joints or connections. Testing these aspects involved examining potential failures under tension load due to various reasons like steel failure, pull-out/pull-through failure, conical concrete break-out, and splitting failure. At A2P, we use different mechanical testing methods, including flexural testing, shear testing, and creep testing. To learn more about A2P’s fastener testing with GreenGirt® composite metal hybrid (CMH) materials, visit greengirt.com.

Flexural Testing: The Science Behind Bending

Imagine bending a metal rod. How much can it bend before breaking or deforming? Flexural testing provides the answer by measuring a material’s behavior under simple beam loading. Data from this test gives insights into the material’s elastic behavior and resistance to deformation, which are key indicators of a fastener’s ability to withstand bending stresses.

Two main factors determined through flexural testing are flexural strength—the maximum stress a material can withstand before breaking when subjected to bending loads—and flexural modulus which measures a material’s resistance to shape change when bent. Not adhering to flexural testing standards can lead to catastrophic failures, like the infamous Tacoma Narrows Bridge collapse in 1940, resulting from inadequate accounting for dynamic bending forces.

Shear Testing: Parallel Forces

Shear testing evaluates how materials respond to forces aiming to deform them. Think of applying pressure on a deck of cards in opposing directions—this technique provides key insights into a material’s shear properties. Determining the shear strength of a material is vital as it gauges its performance under shear stress. This data is particularly crucial when evaluating fastener pull-out and torque behavior—key to ensuring the structural integrity of buildings, bridges, and other structures.

Shear testing isn’t limited to construction; it’s also pivotal in electronics, where it assesses the robustness of solder joints, and aerospace, where it determines the suitability of materials used in aircraft and spacecraft. The testing methods may vary across industries—for instance, the ASTM D732 punch tool technique is commonly used for shear strength testing of plastics. However, the goal remains the same: to quantify a material’s resistance to shear stress.

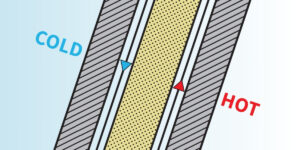

Creep Testing: The Slow Change

Creep testing, on the other hand, examines how materials deform over time under constant stress or load, particularly at elevated temperatures. Think of a metal beam supporting a heavy load in a hot environment—it gradually stretches and deforms. This slow but steady change is known as “creep.”

Creep testing aims to determine a material’s creep rate, or the speed at which it deforms under long-term stress. A low creep rate indicates high durability and resilience, while a high creep rate suggests potential structural issues. Creep testing also plays a key role in evaluating fastener pull-out and torque behavior, essential in industries like construction, aerospace, energy, and transportation.

Conclusion

In sum, A2P’s structural static and mechanical testing practices exemplify our dedication to safety and technical excellence, informed by a deep understanding of the nuances of material behavior under stress. Our thorough mechanical testing practices aren’t just a series of steps—it’s a manifestation of our commitment to ensuring the highest standards in construction projects. Each assignment we undertake is treated with a custom approach, backed by our vast reservoir of industry-specific knowledge and unwavering attention to detail. Our dedication goes beyond our products—it is reflected in our resolute commitment to our clients, delivering robust solutions that cater to their unique needs.

If you are interested in learning more about Advanced Architectural Products and GreenGirt® composite metal hybrid (CMH) Z-girts, visit our website or contact us today.

© 2023 Advanced Architectural Products