You may have heard the term continuous insulation, but what is it really? Knowing what options are on the market in a world of increasing energy prices and demands for better energy efficiency is key to a project’s success and a well-designed, long-lasting building.

When thinking about a building’s energy efficiency, insulation should be top of mind. Use this guide to confidently make decisions on the proper insulation system for your future building projects.

What types of insulation systems are available?

Designing buildings is never easy and requires building owners and designers to make many decisions with different tradeoffs. Choosing the best insulation system and energy-saving option is one of those decisions. Whether you choose no insulation, cavity insulation or continuous insulation, each of these options comes with different upfront costs regarding materials and installation labor as well as the energy cost to operate the building in the future.

Deciding to go without insulation saves a ton of money upfront because you’re not installing anything. The downside is the building will cost much more to operate, will be less comfortable inside and won’t last as long as an insulated building. If the building is conditioned, insulation is critically important and likely required by local codes.

Before choosing a type of insulative material, there are two general systems of adding insulation to a structure: cavity insulation and continuous insulation. Cavity insulation is installed in the cavities of stud wall framing, in between the metal or wooden studs.

Continuous insulation is applied to the exterior of building framing and completely encapsulates the building. Both options are economical and result in a well-insulated building, but there is a significant difference that makes continuous insulation the optimal choice.

What is continuous insulation?

Continuous insulation (CI) is a continuous layer of insulation installed on the exterior of building framing that maximally reduces energy transfer between the building and the surrounding environment. CI is defined by ASHRAE 90.1 as “insulation that is continuous across all structural members without thermal bridges other than fasteners and service openings.” The ASHRAE 90.1 Standard remains a benchmark for commercial building energy codes in the U.S. and is used in many municipal building codes.

To understand what this means and fully appreciate the pros of CI, we must take a look at the concept of thermal bridging as it applies to continuous insulation.

Understanding Thermal Bridging and CI

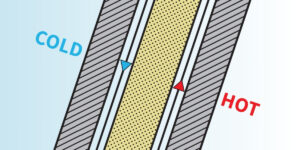

Thermal bridging occurs when there is a path for energy transfer between building envelope components. Wood or steel studs in cavity insulation systems are a great example. When insulation is used in a wall cavity, only the cavities are technically insulated because between each cavity of insulation is a stud (typically wood or steel).

While the properties of wood and steel studs allow for some insulative properties, they are less so than actual insulation, so these breaks in the cavity insulation ultimately allow for energy to transfer through the studs and building envelope. Thermal bridging decreases the effectiveness of the cavity insulation as the energy moves through the connected conductive materials including the cladding and studs.

The key aspect of CI is that it completely wraps the exterior of the building framing rather than insulation just added to cavities between studs. Because the CI system encloses the entire wall — including the studs — the thermal bridging caused by studs can be eliminated in some CI systems.

That said, in some CI systems, thermal bridging will still occur via the through-wall and through-metal fasteners that connect the continuous insulation system and cladding to the structure. While certainly not as strong a thermal bridge as that created by wall studs, a significant amount of energy can escape via these fastening points. To correct this and make continuous insulation truly continuous, proper CI systems such as the GreenGirt® CMH™ (composite metal hybrid) continuous insulation system with GreenGirt® CMH™ Z-girt sub-framing, created by Advanced Architectural Products, completely eliminate thermal bridging by removing through-wall and through-metal fasteners.

What types of insulation are commonly used with CI systems?

As with cavity insulation, many different types of insulation can be used with CI.

Polyisocyanurate (Polyiso)

Polyiso is a type of thermosetting plastic foam. Its closed cells contain a gas that has low conductivity. CI systems with polyiso can take the form of rigid foam boards or laminated insulation panels.

Mineral Wool

This refers to two types of insulating fibers that are man-made. One type of mineral wool is rock wool. Rock wool consists of fibers spun from minerals like basalt. Slag wool is another type of material commonly used in CI systems. Slag wool is made from fibers spun from the waste materials that form on the surface of molten metal.

Spray Foam

Spray foam can be made from polyiso and other materials. The liquid foam is combined with a foaming agent before being sprayed onto the building’s surface. One reason to choose spray foam is that it easily conforms to the surface upon which it is sprayed. However, it does require that installers have special certifications and equipment.

What Are the Benefits of CI?

CI is applied to the exterior framing of a building instead of between the interior studs, so it provides a continuous thermal barrier around the entire exterior of the building. CI is truly an improvement to other traditional insulation solutions. Some of the biggest benefits are:

- Elimination of thermal bridging

- Lower cost of installation

- Increased building life

- Increase in overall building health

- Built-in air, vapor and weather-resistive barrier for the building’s exterior

- Ensures building will easily hit energy standards

- Decreased risk of moisture damage

Elimination of Thermal Bridging

In the same way that a bridge gives people easy access across a waterway, thermal bridging gives heat an easy path to flow through insulation. Insulation acts as a thermal barrier to stop heat from moving, but anytime the insulation is interrupted with conductive materials, a thermal bridge can occur.

Thermal bridging decreases the composite R-value of the entire wall. A wall using R-20 insulation with steel studs can often end up with a composite R-value of 5 due to the thermal bridging from the studs. Best practice CI systems can completely eliminate thermal bridges and give the entire wall a highly effective R-value.

GreenGirt CMH sub-framing is composed of a composite metal hybrid material designed to provide a thermal break yet remain as strong as steel. With two integrated metal fastener retention plates inserted into both flanges of the composite Z-girt, GreenGirt CMH is the strongest yet most thermally efficient best practice CI solution.

Lower Installation Cost

A well-designed CI system keeps both material and labor costs low. No building owner or contractor wants project delays, and issues seem to always cause a ripple effect. Using a GreenGirt CMH system saves time by combining many components into an easy-to-install system.

The GreenGirt CMH Z-girt component inside of the GreenGirt CMH continuous insulation system assembly is made from a composite metal hybrid (CMH) Z-shaped girt that offers rapid installation capability. The GreenGirt CMH system is typically four times faster to install than other insulation methods.

Decreased Moisture-Damage Risk

With through-metal fasteners, water vapor has the potential of condensing on the ends of the fastener. Best practice CI systems reduce the risk of any internal surface temperatures reaching the air’s dewpoint and forming moisture by eliminating the exchange of energy through thermal bridging. Combining these two features results in a better, longer-lasting structure.

The A2P Difference

Designing buildings isn’t easy. Finding the best CI system for your commercial building can be a tough decision too. Our CI experts at Advanced Architectural Products are here to help you find the best continuous insulation solution to move your project forward smoothly.

That is why we created and manufacture various systems, including the GreenGirt CMH continuous insulation and SMARTci building enclosure systems. GreenGirt CMH and SMARTci were created with one goal in mind: to make a more energy-efficient building. Our systems eliminate thermal gaps that other systems neglect and provide best practices for buildings with a CI system, creating the ultimate solution.

Some of the many benefits of our systems include:

- Installation speeds that are 4x faster than standard steel sub-framing

- Compatibility with most types of insulation and cladding

- Up to 98%-thermal efficiency

- ASTM E84 Class A approval (fire and smoke rating)

- UL 94 – Standard for Tests for Flammability of Plastic Materials for Parts in Devices and Appliances

- Complies with NFPA 285 (National Fire Protection Association)

We offer various products to ensure your CI needs are met with each and every project. Contact us or request a custom quote today!

© 2022 Advanced Architectural Products