Introduction

Navigating the complex world of construction materials, professionals are continually faced with choices shaping their projects’ future. Among these, Fiber-Reinforced Polymer vs. Steel stand out as two materials at the forefront of modern construction debates. This article embarks on a detailed exploration of these two pivotal materials, dissecting their properties, applications, and the critical role they play in the industry.

Fiber-reinforced polymer, commonly referred to as FRP, is a composite material that combines a polymer matrix with reinforcing fibers like glass, carbon, or aramid. It’s celebrated for its remarkable strength-to-weight ratio, resistance to corrosive elements, and flexibility in design. FRP is an increasingly popular choice across various sectors, notably in scenarios where traditional materials might falter due to environmental challenges.

Conversely, steel, an enduring symbol of industrial might, is an alloy primarily composed of iron and carbon. It is ubiquitous in construction as a testament to its proven strength, resilience, and versatility. Steel’s ability to withstand the test of time and its inherent recyclability make it a go-to material for projects demanding reliability and endurance.

Choosing a suitable material is a cornerstone decision in any construction or engineering project. This choice influences not just the project’s initial feasibility and cost but also its long-term viability and impact. As we navigate the comparative world of FRP and Steel, this article aims to give you a nuanced understanding, highlighting how each material could potentially shape your construction endeavors’ efficiency, sustainability, and durability.

Understanding Fiber-Reinforced Polymer (FRP)

Definition and Composition of Fiber-Reinforced Polymer

Fiber-reinforced polymer (FRP) is a composite material that combines a polymer matrix with reinforcing fibers. The matrix, typically a type of plastic such as epoxy, polyester, or vinyl ester, binds the fibers together and distributes loads between them. The fibers, usually made of glass (GFRP), carbon (CFRP), or aramid (AFRP), provide strength and stiffness to the composite. This synergistic combination results in a material that exhibits enhanced properties unachievable by the individual components alone.

Manufacturing Process and Fiber Types

The manufacturing of FRP involves several processes, each tailored to the end application’s specific requirements. Common methods include pultrusion, where fibers are pulled through a resin and cured to form profiles; lay-up, where layers of fiber and resin are manually or automatically placed and cured; and filament winding, used to create hollow, circular shapes like pipes and tanks. The type of fiber used significantly influences the FRP’s properties.

- Glass Fibers (GFRP): Offer a good balance of strength and cost-effectiveness, making them suitable for various applications.

- Carbon Fibers (CFRP): Provide exceptional strength and stiffness with a lower weight, ideal for high-performance needs.

- Aramid Fibers (AFRP): Known for their impact resistance and strength, used in applications requiring durability.

Key Properties of FRP

FRP materials are characterized by several key properties that make them attractive in various applications:

- High Strength-to-Weight Ratio: FRP can be stronger per unit of weight than metals, making them ideal for lightweight structures.

- Corrosion Resistance: Unlike metals, FRP does not corrode, making it suitable for harsh environmental conditions.

- Flexibility in Design: FRP can be molded into complex shapes, offering design flexibility that is often challenging with traditional materials.

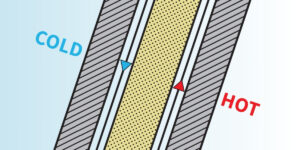

- Thermal and Electrical Insulation: FRP is an excellent insulator, making it suitable for electrical and thermal applications.

Advantages and Disadvantages of FRP

While FRP presents a range of benefits, it also comes with its considerations:

- Advantages:

- Corrosion Resistance: Resistant to corrosion, rot, and moisture.

- Low Maintenance: Requires less upkeep over time due to its resistance to environmental factors.

- Thermal Efficiency: Acts as an insulator, helping maintain temperature control and energy efficiency in structures.

- Customization: Can be engineered to meet specific performance requirements.

- Disadvantages:

- Low Durability: Certain types of FRP can be prone to wear and degradation under repetitive stress or in harsh environmental conditions.

- Low Fastener Retention: Fastening FRP can be challenging due to its low holding power compared to metals, leading to concerns over long-term reliability and structural integrity.

Fiber-reinforced polymer presents itself as a compelling material choice with its notable advantages, including thermal efficiency, design versatility, thermal efficiency, and corrosion resistance. However, understanding its limitations in structural strength, specific durability concerns, and fastening challenges is essential for anyone considering FRP for their next project. As technology and material science advance, the capabilities and applications of FRP are expected to expand.

Understanding Steel

Brief History and Production of Steel

Steel’s journey is as old as civilization itself, with its earliest forms dating back to 1800 BCE. However, it was the invention of the Bessemer process in the 1850s that revolutionized steel production, making it more efficient and affordable and paving the way for the modern world’s fastest infrastructure. (1)(2) Today, steel is produced through methods like basic oxygen steelmaking, where oxygen is blown through molten iron to reduce carbon content, and electric furnaces, which melt recycled steel scrap for reuse. (3)

Types of Steel Used in Construction and Their Properties

Steel’s versatility comes from its ability to take on different properties through alloying and treatment. Common types of steel in construction include:

- Carbon Steel: The most basic form, varying in carbon content from low to high, affecting its strength and ductility.

- Alloy Steel: Enhanced with various elements like manganese, chromium, and nickel for improved strength, hardness, or corrosion resistance.

- Stainless Steel: Known for its corrosion resistance, owing to a significant chromium content. It’s ideal for aesthetic architectural elements and environments prone to corrosion.

- Tool Steel: Contains elements like tungsten and cobalt to increase heat resistance and durability, often used in cutting and drilling equipment.

Key Benefits and Typical Applications of Steel

Steel’s predominance in construction can be attributed to its numerous benefits:

- Strength and Durability: Offers high tensile strength and can withstand considerable stress and weight, making it suitable for high-rise buildings, bridges, and other demanding structures.

- Versatility: Steel can be fabricated into almost any shape, catering to diverse design requirements.

- Recyclability: Steel can be recycled without degradation of its properties, promoting sustainable construction practices. Typical applications include structural frameworks, reinforcement bars in concrete, roofing, and facades, among others.

Advantages and Disadvantages of Steel

Like any material, steel has its pros and cons:

- Advantages:

- High Strength: Steel’s foremost advantage is its exceptional strength, providing a solid foundation for buildings and infrastructure.

- Durability: Resistant to many forms of wear and tear, steel structures and building materials can last for decades with proper maintenance.

- Fastener Retention: Steel’s high tensile strength and rigidity ensure that fasteners like bolts, screws, and rivets maintain tight connections, providing long-term structural stability and safety.

- Disadvantages:

- Corrosion: Vulnerable to rust and corrosion if not correctly treated.

- Thermal Conductivity: Conducts heat, posing challenges in fires and insulation.

As a foundational material in construction, steel’s benefits, from high strength to excellent fastener retention, make it indispensable. However, understanding its advantages and vulnerabilities, such as corrosion and thermal conductivity, is crucial for any project.

Comparative Analysis: Fiber-Reinforced Polymer vs Steel

A comparative analysis of fiber-reinforced polymer (FRP) and steel is essential in the quest for the most suitable construction materials. Understanding how each performs regarding strength, weight, corrosion resistance, and maintenance can guide architects, engineers, and builders in making informed decisions.

Strength and Durability

- FRP: FRP’s strength-to-weight ratio is its most significant advantage. However, FRP generally has lower compressive strength than steel, which means it might not absorb and redistribute impacts and loads the same way steel does. Its durability is also influenced by composite components such as resin and fibers, with some being more susceptible to environmental degradation over time.

- Steel: Steel is renowned for its high tensile and compressive strength, making it a standard for load-bearing structures. It’s capable of enduring significant physical stress, impacts, and heavy loads without compromising its integrity. However, corrosion can compromise its durability if not adequately protected or maintained.

Applications in Construction and Engineering

The choice between fiber-reinforced polymer (FRP) and steel significantly influences the success and sustainability of construction and engineering projects. We can better understand their optimal uses by examining specific scenarios where one material is preferred over the other, mainly focusing on non-structural applications for FRP and structural components for steel.

FRP in Non-Structural Applications:

- Facades and Architectural Features: FRP is often chosen for architectural applications due to its ability to be molded into complex shapes and its wide range of finishes. For instance, FRP panels are used in modern buildings for their aesthetic appeal and lightweight nature.

- Utility and Service Pipes: Due to its corrosion resistance and durability, FRP is preferred for pipes and conduits, especially in corrosive environments or where lightweight installations are beneficial.

Steel in Structural Components:

- High-Rise Buildings: Steel’s high strength makes it the material of choice for the structural framework, from commercial buildings to skyscrapers.

- Bridges: Steel is predominantly used in bridges for its ability to withstand heavy loads and its durability, especially in critical components such as framing, beams, and girders.

- Industrial Facilities: Steel’s robustness and ability to span large distances without support make it ideal for the structural elements of factories and warehouses.

The Future of FRP and Steel in Construction: Composite Metal Hybrid (CMH™)

The future of construction and engineering is poised to be revolutionized by innovative hybrid components that synergize the strengths of different materials. One of the most prominent materials in this arena is the integration of fiber-reinforced polymer (FRP) and steel, creating composite systems that deliver superior performance and efficiency. A prime example of this innovative approach are the GreenGirt® CMHᵀᴹ (composite metal hybrid) continuous insulation and SMARTci® building enclosure systems, featuring GreenGirt CMH Z-girts.

GreenGirt® Composite Metal Hybrid (CMH™) Z-girts:

GreenGirt CMH Z-girts exemplify the fusion of FRP and steel, harnessing the best properties of both to offer a superior building material. It consists of a structural composite Z-profile and continuous interlocking metal inserts in both the front and back flanges, which combines FRP’s lightweight, corrosion-resistant nature with the strength, fastener retention, and rigidity of steel. This hybrid approach is designed as a versatile, high-performance building envelope, offering enhanced insulation, structural support, durability, and longevity.

GreenGirt CMH continuous insulation and SMARTci building enclosure systems have been successfully implemented in various projects, demonstrating their effectiveness in real-world scenarios. GreenGirt CMH and SMARTci represents a leap forward in building technology, offering a solution that addresses many of the traditional limitations of standalone materials. As the industry continues to grow, we can expect to see more buildings with GreenGirt CMH sub-framing systems, each designed to meet the evolving needs of modern construction. By intelligently combining the strengths of FRP and steel, this advanced material paves the way for more efficient, safer, durable, and sustainable buildings.

Choosing the Right Material for Your Project

Selecting the most appropriate material for your construction or engineering project is a critical decision that influences the project’s immediate success and its long-term viability. Here’s how you can assess project needs against the properties of fiber-reinforced polymer (FRP), steel, or GreenGirt CMH (composite metal hybrid) and expert advice on consulting with professionals.

When selecting materials for your project, we encourage you to:

- Assess Project Needs:

- Understand the Environment

- Consider the Application

- Evaluate Long-Term Performance

- Analyze Cost Implications

- Consult with Experts:

- Engage with Engineers

- Talk to Material Specialists

- Consider Custom Solutions

In conclusion, choosing between FRP, steel, or GreenGirt CMH requires carefully evaluating your project’s specific needs, environmental conditions, safety requirements, and long-term goals. Consulting with engineers and material specialists will provide the insights needed to make an informed decision, ensuring that the chosen material aligns with the project’s requirements, budget, and expected lifespan. You can select the most appropriate and efficient material for your project by thoroughly assessing all these factors.

Conclusion

We have explored the distinctive characteristics, applications, and implications of using fiber-reinforced polymer (FRP) vs steel in modern construction and engineering projects. FRP stands out for its high strength-to-weight ratio, corrosion resistance, and design flexibility, making it ideal for non-structural and specialized applications. On the other hand, steel is celebrated for its robust structural integrity, durability, and versatility, serving as the backbone of numerous architectural marvels.

The advent of GreenGirt CMH (composite metal hybrid) sub-framing represents a significant leap forward, marrying the best properties of FRP and steel. This innovative hybrid delivers enhanced thermal efficiency, structural strength, and environmental resistance, offering a balanced solution that addresses many traditional material limitations.

As the construction industry continues to evolve, the development and optimization of CMH systems are set to play a pivotal role. These advancements promise to elevate the quality and efficiency of future structures and reflect a broader commitment to innovation, sustainability, and excellence in the field. By embracing these hybrid composite solutions, the industry is poised to meet the complex demands of modern construction with greater adaptability, responsibility, and foresight.

To learn more about GreenGirt CMH (composite metal hybrid) sub-framing, please visit our website or contact us today!

Sources:

- https://www.britannica.com/technology/steel/History

- https://blogs.loc.gov/inside_adams/2012/12/andrew-carnegie-man-of-steel/

- https://uk.emrgroup.com/find-out-more/latest-news/journey-of-metals-steelmaking

© 2024 Advanced Architectural Products