I. Introduction

In the vast realm of construction, building integrity is paramount. It is not merely about aesthetics or functionality; structural integrity ensures a structure’s safety, durability, and long-term performance. Every component, including Z-girts, plays a vital role in maintaining this integrity. Compromising any of these components can lead to degradation, reduced lifespan, and, in severe cases, catastrophic failures.

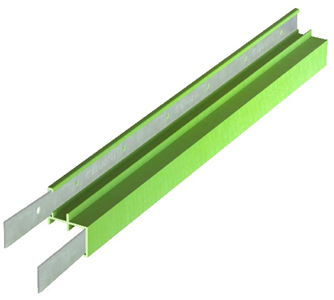

Enter the metal Z-girt — a seemingly inconspicuous component that has found its niche in the construction industry. Z-girts, metal channels used primarily for attaching exterior cladding and supporting insulation, are prevalent in commercial and residential construction. Their straightforward design and ease of installation have made them a staple in modern building techniques. However, metal Z-girts have strengths and potential vulnerabilities like all building materials. As we delve deeper into building degradation, particularly from corrosion and moisture, it’s essential to understand the role of these metal girts and question if they might be a contributing factor.

In the following sections, we will explore the science of corrosion, the relationship between moisture and building materials, and, most importantly, assess the performance and potential risks associated with metal Z-girts in this context.

II. The Science of Corrosion

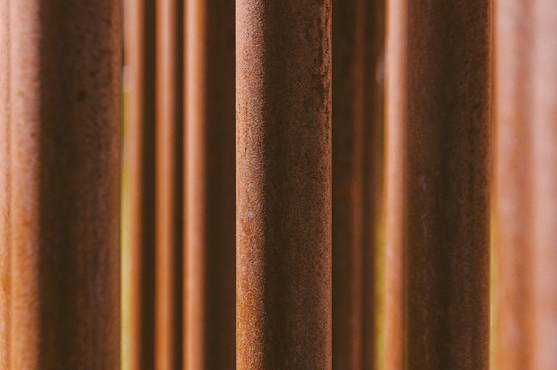

Corrosion, at its core, is the natural process by which metal materials deteriorate due to their environment. It’s a chemical or electrochemical reaction that occurs when metals, such as steel or iron, react with surrounding elements, forming oxides, hydroxides, or sulfides. Imagine the reddish-brown flaky substance you often see on old iron objects; rust is a common result of iron corrosion.

Several factors can instigate or accelerate the corrosion process. Some of the most common causes include:

- Oxygen and Moisture: In the presence of water, metals can react with oxygen, leading to oxidation. This combination is perhaps the most common cause of corrosion, especially in metals like iron.

- Salts and Chemicals: Environments rich in salts, especially those with chloride ions, can significantly speed up corrosion. Similarly, exposure to certain chemicals can react with metals, causing them to corrode.

- pH Levels: Extremely high or low pH levels in the environment can be corrosive to metals. For example, acidic rain can lead to accelerated corrosion of structures.

- Galvanic Reactions: When two dissimilar metals come into contact with an electrolyte (like saltwater), a galvanic reaction can occur, leading to the corrosion of one of the metals.

Environmental factors play a significant role in the rate and extent of metal degradation. Coastal areas, where the air is laden with salt, often see faster corrosion rates in exposed metal structures. Similarly, urban environments with high pollution levels can lead to acid rain, which can harm metal components. Temperature fluctuations, humidity levels, and even the presence of specific microbes can all influence how and how quickly metals corrode.

It is essential to understand that while all metals can corrode, the rate and form of corrosion can vary widely based on the type of metal and its environment. For construction materials, especially those as prevalent as metal Z-girts, recognizing and mitigating these factors can ensure longevity and structural integrity.

III. The Role of Moisture

Moisture is a pivotal player in the corrosion process. At a basic level, the presence of water facilitates the electrochemical reactions that lead to the degradation of metals. When metals come into contact with water they undergo oxidation. This oxidation process results in the formation of metal oxides, commonly known as rust in the case of iron. Combining water and oxygen, especially in environments rich in salts or other corrosive agents, can accelerate this process manifold.

Building envelopes, or wall assemblies, which are the physical separators between the conditioned and unconditioned environment of a building, are especially vulnerable to moisture accumulation. Several conditions can promote this moisture buildup within a wall cavity:

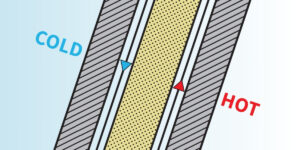

Thermal Bridging

This refers to areas in the building envelope with higher thermal conductivity than the surrounding materials, allowing heat to pass through more readily. For example, metal panels are attached with metal fasteners to metal Z-girts, which are then attached to metal studs. All these metal components, including the metal Z-girts, can act as thermal bridges, leading to differences in temperature on either side. Such temperature differences can result in condensation, providing the moisture necessary for corrosion. The presence of thermal bridges within the building envelope not only increases the risk of corrosion but also reduces the overall thermal efficiency and structural integrity of the building.

Inadequate Waterproofing

Without appropriate sealant or proper waterproofing measures, rainwater or groundwater can seep into the building envelope, providing a constant source of moisture.

Differential Pressure

Differences in air pressure between the inside and outside of a building can drive moist air into the building envelope, where it can condense on cooler surfaces.

The dangers of unchecked moisture within wall assemblies extend beyond just corrosion. Prolonged exposure to moisture can lead to mold growth, which poses health risks to occupants and can degrade organic building materials. Additionally, moisture can compromise the structural integrity of certain materials, leading to failures or reduced lifespan. For instance, wooden components can rot, and insulation can lose effectiveness when wet. Furthermore, moisture can facilitate the movement of salts and other corrosive agents, further exacerbating the corrosion process.

In construction and building maintenance, understanding the role of moisture and taking proactive measures to manage it is crucial. Not only does it preserve the integrity of metal components, but it also ensures the entire structure’s longevity, safety, and efficiency.

IV. Z-Girts: A Close Examination

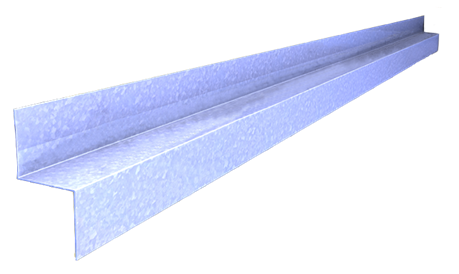

Z-girts, often referred to as girts, are vertical or horizontal metal channels that play a fundamental role in the construction world, particularly in the realm of exterior building envelope systems. These channels, usually shaped like the letter “Z,” are designed to bridge the gap between the structural components of a building and its external façade, whether it be cladding, insulation, or other materials. Their unique shape allows for efficient attachment points while providing an offset between the primary structure and the exterior layer. This offset is particularly useful in facilitating insulation, drainage, and ventilation behind the cladding material.

Historically, the use of girts or similar channels can be traced back to the evolution of modern building techniques that aimed for enhanced energy efficiency, resilience, and architectural flexibility. The need for intermediary attachment systems, like Z-girts, became evident as the construction industry moved away from monolithic wall systems toward layered envelopes with distinct structural, insulating exterior insulation, and aesthetic components.

Over the years, the materials used to manufacture Z-girts have evolved significantly. Initial girts were predominantly made of steel, prized for its strength and rigidity. However, as we deepen our understanding of thermal bridging and the importance of continuous insulation, the industry began to recognize the potential drawbacks of steel girts. Highly conductive steel can act as a thermal bridge, compromising the building’s thermal envelope and leading to inefficiencies.

This realization spurred innovation, leading to the exploration of alternative materials and designs. The adaptation of composite materials, hybrids, and advanced coatings aimed to retain the strength of traditional girts while reducing or eliminating their thermal bridging potential. However, it’s worth noting that while composite-only materials do offer corrosion resistance, they DO NOT provide the same structural integrity necessary in building envelopes compared to traditional steel girts.

This challenge led to the development of hybrid solutions like GreenGirt® Composite Metal Hybrid (CMHᵀᴹ), a Z-girt that marries the best of both worlds: metal girts’ structural integrity and non-conductive materials’ thermal performance.

Z-girts are a testament to the industry’s adaptability and relentless pursuit of better, more efficient solutions in the grand scheme of building evolution. Their journey from simple steel channels to advanced composite metal hybrid (CMH) girts reflects the broader shifts in construction philosophy, emphasizing sustainability, efficiency, and performance.

V. Potential Vulnerabilities of Z-Girts in a Wall Assembly

Z-girts, while integral to many modern building systems, have vulnerabilities. A close examination of the materials and design choices in girts reveals potential weak points that can compromise their performance and longevity.

- Materials and Their Implications:

- Metal Z-Girts: Traditional girts have predominantly been constructed from steel, offering structural strength but presenting specific susceptibilities. Steel’s tendency to degrade, especially when left unprotected, can lead to concerns about longevity and performance. In response to these challenges, composite materials have emerged as an alternative.

- Composite Z-Girts: Composites are engineered materials made from two or more constituent materials with significantly different physical or chemical properties. When combined, they produce a material with characteristics different from the individual components, often aiming to capitalize on the strengths of each while mitigating their weaknesses.

- Non-Metallic Nature: Most composites in construction and engineering applications combine polymer resins and reinforcing fibers, such as fiberglass or carbon fiber. Neither the resin matrix nor the reinforcing fibers are metallic, meaning they don’t undergo the same oxidation process as metals like iron when exposed to moisture and oxygen. This inherent characteristic makes them resistant to the formation of rust or other metal oxides.

- Inert Chemistry: The chemical structure of many composites makes them inert or passive to a wide range of environmental conditions. They do not readily react with most of the corrosive agents in the environment, be it salts, acids, or other chemicals.

- Absence of Electrochemical Reactions: Corrosion in metals is often an electrochemical process. Since composites are non-conductive, they do not support these electrochemical reactions, which are central to the corrosion process in metals.

- Barrier Properties: Many composites possess excellent barrier properties, preventing the penetration of moisture, salts, and other corrosive agents into the material. This further reduces the potential for any corrosive process to start.

- Customizability: Depending on the intended application, composites can be engineered with specific resins or additives that further enhance their resistance to specific environmental challenges.

In summary, composite materials’ very structure and chemistry make them inherently resistant to the processes that lead to metal corrosion. This resistance, combined with their versatility and adaptability, has made them an attractive choice for numerous applications.

- Real-World Implications: Varied geographical and climatic conditions have revealed distinct challenges associated with girts. For instance, properties along coastlines have sometimes shown premature wear due to the hastened corrosion of their girts. In colder regions, the very design of some girts has inadvertently contributed to moisture retention, leading to broader issues like mold growth.

Given these challenges, construction industry professionals must be discerning in their choice and application of girts. Whether it’s through the adoption of alternative materials, innovative designs, or protective measures, optimizing the performance and lifespan of these crucial components is paramount.

V. Potential Vulnerabilities of Z-Girts in a Wall Assembly

Z-girts, while integral to many modern building systems, have vulnerabilities. A close examination of the materials and design choices in girts reveals potential weak points that can compromise their performance and longevity.

Materials and Their Implications:

- Metal Z-Girts: Traditional girts have predominantly been constructed from steel, offering structural strength but presenting specific susceptibilities. Steel’s tendency to degrade, especially when left unprotected, can lead to concerns about longevity and performance. In response to these challenges, composite materials have emerged as an alternative.

- Composite Z-Girts: Composites are engineered materials made from two or more constituent materials with significantly different physical or chemical properties. When combined, they produce a material with characteristics different from the individual components, often aiming to capitalize on the strengths of each while mitigating their weaknesses.

- Non-Metallic Nature: Most composites in construction and engineering applications combine polymer resins and reinforcing fibers, such as fiberglass or carbon fiber. Neither the resin matrix nor the reinforcing fibers are metallic, meaning they don’t undergo the same oxidation process as metals like iron when exposed to moisture and oxygen. This inherent characteristic makes them resistant to the formation of rust or other metal oxides.

- Inert Chemistry: The chemical structure of many composites makes them inert or passive to a wide range of environmental conditions. They do not readily react with most of the corrosive agents in the environment, be it salts, acids, or other chemicals.

- Absence of Electrochemical Reactions: Corrosion in metals is often an electrochemical process. Since composites are non-conductive, they do not support these electrochemical reactions, which are central to the corrosion process in metals.

- Barrier Properties: Many composites possess excellent barrier properties, preventing the penetration of moisture, salts, and other corrosive agents into the material. This further reduces the potential for any corrosive process to start.

- Customizability: Depending on the intended application, composites can be engineered with specific resins or additives that further enhance their resistance to specific environmental challenges.

In summary, composite materials’ very structure and chemistry make them inherently resistant to the processes that lead to metal corrosion. This resistance, combined with their versatility and adaptability, has made them an attractive choice for numerous applications.

Real-World Implications

Varied geographical and climatic conditions have revealed distinct challenges associated with girts. For instance, properties along coastlines have sometimes shown premature wear due to the hastened corrosion of their girts. In colder regions, the very design of some girts has inadvertently contributed to moisture retention, leading to broader issues like mold growth.

Given these challenges, construction industry professionals must be discerning in their choice and application of girts. Whether it’s through the adoption of alternative materials, innovative designs, or protective measures, optimizing the performance and lifespan of these crucial components is paramount.

VI. Comparing Traditional Z-Girts to Alternative Hybrids

The quest for improved materials and systems is unending. While traditional metal girts have long held a significant position, innovations like the GreenGirt Composite Metal Hybrid (CMH) Z-girt have emerged as compelling alternatives.

A groundbreaking blend of metal and composite, the GreenGirt CMH Z-girt stands as a testament to the advancements in construction material technology. It’s not just a hybrid in name; this system ingeniously combines the best attributes of both its constituents. Unlike composite-only girts, which compromise on structural strength, or metal girts prone to thermal bridging and corrosion, the GreenGirt CMH girt strikes a harmonious balance.

Several distinct benefits set the GreenGirt CMH Z-girt apart:

- Moisture Resistance: As previously discussed, one of the primary challenges with traditional metal girts is their vulnerability to moisture. GreenGirt CMH, with its composite Z-profile, eliminates thermal bridging by creating a thermal break between cladding, insulation, and structural framing materials. GreenGirt CMH Z-girts eliminate the risk of condensation or dampness by eliminating thermal bridging.

- Corrosion Resistance: The unique composition of GreenGirt CMH Z-girts significantly reduces susceptibility to corrosion. While the metal components provide the needed structural rigidity, the composite Z-profile is a barrier against corrosive agents.

- Electrochemical Stability: Traditional metal girts can undergo electrochemical reactions when exposed to certain environments, leading to accelerated degradation. GreenGirt CMH’s hybrid nature ensures that such reactions are minimized if not entirely eliminated.

- Structural Integrity: A standout feature of the GreenGirt CMH Z-girt is its continuous metal presence in front and back flanges. This design choice ensures that while the girt benefits from the insulating properties of the composite, there’s no compromise on its structural strength or fastener retention.

V. Potential Vulnerabilities of Z-Girts in a Wall Assembly

Z-girts, while integral to many modern building systems, have vulnerabilities. A close examination of the materials and design choices in girts reveals potential weak points that can compromise their performance and longevity.

- Materials and Their Implications:

- Metal Z-Girts: Traditional girts have predominantly been constructed from steel, offering structural strength but presenting specific susceptibilities. Steel’s tendency to degrade, especially when left unprotected, can lead to concerns about longevity and performance. In response to these challenges, composite materials have emerged as an alternative.

- Composite Z-Girts: Composites are engineered materials made from two or more constituent materials with significantly different physical or chemical properties. When combined, they produce a material with characteristics different from the individual components, often aiming to capitalize on the strengths of each while mitigating their weaknesses.

- Non-Metallic Nature: Most composites in construction and engineering applications combine polymer resins and reinforcing fibers, such as fiberglass or carbon fiber. Neither the resin matrix nor the reinforcing fibers are metallic, meaning they don’t undergo the same oxidation process as metals like iron when exposed to moisture and oxygen. This inherent characteristic makes them resistant to the formation of rust or other metal oxides.

- Inert Chemistry: The chemical structure of many composites makes them inert or passive to a wide range of environmental conditions. They do not readily react with most of the corrosive agents in the environment, be it salts, acids, or other chemicals.

- Absence of Electrochemical Reactions: Corrosion in metals is often an electrochemical process. Since composites are non-conductive, they do not support these electrochemical reactions, which are central to the corrosion process in metals.

- Barrier Properties: Many composites possess excellent barrier properties, preventing the penetration of moisture, salts, and other corrosive agents into the material. This further reduces the potential for any corrosive process to start.

- Customizability: Depending on the intended application, composites can be engineered with specific resins or additives that further enhance their resistance to specific environmental challenges.

In summary, composite materials’ very structure and chemistry make them inherently resistant to the processes that lead to metal corrosion. This resistance, combined with their versatility and adaptability, has made them an attractive choice for numerous applications.

- Real-World Implications: Varied geographical and climatic conditions have revealed distinct challenges associated with girts. For instance, properties along coastlines have sometimes shown premature wear due to the hastened corrosion of their girts. In colder regions, the very design of some girts has inadvertently contributed to moisture retention, leading to broader issues like mold growth.

Given these challenges, construction industry professionals must be discerning in their choice and application of girts. Whether it’s through the adoption of alternative materials, innovative designs, or protective measures, optimizing the performance and lifespan of these crucial components is paramount.

VI. Comparing Traditional Z-Girts to Alternative Hybrids

The quest for improved materials and systems is unending. While traditional metal girts have long held a significant position, innovations like the GreenGirt Composite Metal Hybrid (CMH) Z-girt have emerged as compelling alternatives.

A groundbreaking blend of metal and composite, the GreenGirt CMH Z-girt stands as a testament to the advancements in construction material technology. It’s not just a hybrid in name; this system ingeniously combines the best attributes of both its constituents. Unlike composite-only girts, which compromise on structural strength, or metal girts prone to thermal bridging and corrosion, the GreenGirt CMH girt strikes a harmonious balance.

Several distinct benefits set the GreenGirt CMH Z-girt apart:

Moisture Resistance

As previously discussed, one of the primary challenges with traditional metal girts is their vulnerability to moisture. GreenGirt CMH, with its composite Z-profile, eliminates thermal bridging by creating a thermal break between cladding, insulation, and structural framing materials. GreenGirt CMH eliminates the risk of condensation or dampness by eliminating thermal bridging.

Corrosion Resistance

The unique composition of GreenGirt CMH significantly reduces its susceptibility to corrosion. While the metal components provide the needed structural rigidity, the composite Z-profile is a barrier against corrosive agents.

Electrochemical Stability

Traditional metal girts can undergo electrochemical reactions when exposed to certain environments, leading to accelerated degradation. GreenGirt CMH’s hybrid nature ensures that such reactions are minimized if not entirely eliminated.

Structural Integrity

A standout feature of the GreenGirt CMH is its continuous metal presence in front and back flanges. This design choice ensures that while the girt benefits from the insulating properties of the composite, there’s no compromise on its structural strength or fastener retention.

VII. Superiority in Structure and Thermal Performance

When stacked against traditional metal or composite-only girts, GreenGirt CMH showcases undeniable superiority. Structurally, it matches, if not exceeds, the loading capabilities of its metal counterparts. Thermally, the inclusion of composite material eliminates the potential for thermal bridging, a common concern with metal girts. This dual advantage ensures that buildings utilizing GreenGirt CMH benefit from enhanced energy efficiency without sacrificing structural robustness.

V. Potential Vulnerabilities of Z-Girts in a Wall Assembly

Z-girts, while integral to many modern building systems, have vulnerabilities. A close examination of the materials and design choices in girts reveals potential weak points that can compromise their performance and longevity.

Materials and Their Implications:

Metal Z-Girts:

Traditional girts have predominantly been constructed from steel, offering structural strength but presenting specific susceptibilities. Steel’s tendency to degrade, especially when left unprotected, can lead to concerns about longevity and performance. In response to these challenges, composite materials have emerged as an alternative.

Composite Z-Girts:

Composites are engineered materials made from two or more constituent materials with significantly different physical or chemical properties. When combined, they produce a material with characteristics different from the individual components, often aiming to capitalize on the strengths of each while mitigating their weaknesses.

- Non-Metallic Nature: Most composites in construction and engineering applications combine polymer resins and reinforcing fibers, such as fiberglass or carbon fiber. Neither the resin matrix nor the reinforcing fibers are metallic, meaning they don’t undergo the same oxidation process as metals like iron when exposed to moisture and oxygen. This inherent characteristic makes them resistant to the formation of rust or other metal oxides.

- Inert Chemistry: The chemical structure of many composites makes them inert or passive to a wide range of environmental conditions. They do not readily react with most of the corrosive agents in the environment, be it salts, acids, or other chemicals.

- Absence of Electrochemical Reactions: Corrosion in metals is often an electrochemical process. Since composites are non-conductive, they do not support these electrochemical reactions, which are central to the corrosion process in metals.

- Barrier Properties: Many composites possess excellent barrier properties, preventing the penetration of moisture, salts, and other corrosive agents into the material. This further reduces the potential for any corrosive process to start.

- Customizability: Depending on the intended application, composites can be engineered with specific resins or additives that further enhance their resistance to specific environmental challenges.

In summary, composite materials’ very structure and chemistry make them inherently resistant to the processes that lead to metal corrosion. This resistance, combined with their versatility and adaptability, has made them an attractive choice for numerous applications.

Real-World Implications

Varied geographical and climatic conditions have revealed distinct challenges associated with girts. For instance, properties along coastlines have sometimes shown premature wear due to the hastened corrosion of their girts. In colder regions, the very design of some girts has inadvertently contributed to moisture retention, leading to broader issues like mold growth.

Given these challenges, construction industry professionals must be discerning in their choice and application of girts. Whether it’s through the adoption of alternative materials, innovative designs, or protective measures, optimizing the performance and lifespan of these crucial components is paramount.

VI. Comparing Traditional Z-Girts to Alternative Hybrids

The quest for improved materials and systems is unending. While traditional metal girts have long held a significant position, innovations like the GreenGirt Composite Metal Hybrid (CMH) Z-girt have emerged as compelling alternatives.

A groundbreaking blend of metal and composite, the GreenGirt CMH Z-girt stands as a testament to the advancements in construction material technology. It’s not just a hybrid in name; this system ingeniously combines the best attributes of both its constituents. Unlike composite-only girts, which compromise on structural strength, or metal girts prone to thermal bridging and corrosion, the GreenGirt CMH girt strikes a harmonious balance.

Several distinct benefits set the GreenGirt CMH Z-girt apart:

Moisture Resistance

As previously discussed, one of the primary challenges with traditional metal girts is their vulnerability to moisture. GreenGirt CMH, with its composite Z-profile, eliminates thermal bridging by creating a thermal break between cladding, insulation, and structural framing materials. GreenGirt CMH Z-girts eliminate the risk of condensation or dampness by eliminating thermal bridging.

Corrosion Resistance

The unique composition of GreenGirt CMH Z-girts significantly reduces its susceptibility to corrosion. While the metal components provide the needed structural rigidity, the composite Z-profile is a barrier against corrosive agents.

Electrochemical Stability

Traditional metal girts can undergo electrochemical reactions when exposed to certain environments, leading to accelerated degradation. GreenGirt CMH Z-girt’s hybrid nature ensures that such reactions are minimized if not entirely eliminated.

Structural Integrity

A standout feature of the GreenGirt CMH is its continuous metal presence in front and back flanges. This design choice ensures that while the girt benefits from the insulating properties of the composite, there’s no compromise on its structural strength or fastener retention.

VII. Superiority in Structure and Thermal Performance

When stacked against traditional metal or composite-only girts, GreenGirt CMH showcases undeniable superiority. Structurally, it matches, if not exceeds, the loading capabilities of its metal counterparts. Thermally, the inclusion of composite material eliminates the potential for thermal bridging, a common concern with metal girts. This dual advantage ensures that buildings utilizing GreenGirt CMH benefit from enhanced energy efficiency without sacrificing structural robustness.

VIII. Conclusion

The intricate dance of construction involves myriad components, each playing its role in the greater symphony of building design and integrity. Among these, girts, particularly those of metal constitution, have emerged as both a boon and a concern. While their structural advantages are undeniable, their susceptibility to corrosion and moisture-induced degradation poses potential pitfalls.

It’s imperative to recognize that in the ever-evolving world of construction, resting on the laurels of tradition can sometimes come at a cost. The risks associated with metal girts, especially in the face of environmental adversities, underscore the need for proactive decision-making. Merely being aware isn’t enough; it’s the actionable steps, the choices made in materials and preventative measures, that truly make the difference.

In this context, introducing alternative hybrids like GreenGirt CMH is not merely a nod to innovation but a tangible step toward enhanced building resilience. Offering a harmonious blend of strength and resistance, GreenGirt CMH stands as a testament to what’s possible when tradition meets innovation. For those at the helm of construction decisions, it’s an invitation to embrace the future to opt for materials that ensure not just aesthetic appeal or immediate functionality but a structure’s long-term performance and longevity.

As we stand at the crossroads of material choices, may we always choose the product that leads to safer, more durable, and more efficient buildings for all.

If you want to learn more about GreenGirt CMH Z-girts, please visit our website or contact us today.

© 2023 Advanced Architectural Products