Projects pursuing PHIUS (Passive House Institute United States) certification depend on a thermally robust, airtight, and well‑detailed enclosure. The GreenGirt CMH™ continuous insulation and SMARTci® building enclosure systems are engineered to reduce thermal bridging at cladding attachments, support airtightness strategies, and streamline installation without sacrificing structural reliability. This article outlines how these systems adhere to PHIUS priorities and practical specification and provides quality assurance tips for designing and constructing with GreenGirt CMH and SMARTci.

A Quick Look at PHIUS Goals

PHIUS emphasizes passive conservation first, and include the following objectives:

- Thermal Bridge-Free Design. Walls must have continuous insulation and building enclosures that not only eliminate thermal bridging but maximize comfort and energy efficiency.

- Airtight Construction. Airtightness must be designed for both durability and energy efficiency by minimizing infiltration of outside air and loss of conditioned air.

- High-Performance Windows. Integrate insulated frames to prevent thermal loss at building openings.

- Heat Recovery Ventilation (HRV). Provide fresh air while recovering heat from the exhaust air.

- High-Quality Insulation. The insulation should ensure minimal heat transfer, keeping indoor spaces comfortable year-round.

The Role of Continuous Insulation and Cladding Attachments in PHIUS Initiatives

ASHRAE 90.1 defines continuous insulation as insulation “uncompressed and continuous across all structural members without thermal bridges other than fasteners and service openings.” Yet, cladding support can reintroduce significant thermal bridges. Using a composite metal hybrid solution to cladding support can eliminate thermal bridging without sacrificing structural integrity or other performance requirements of building envelopes.

GreenGirt CMH

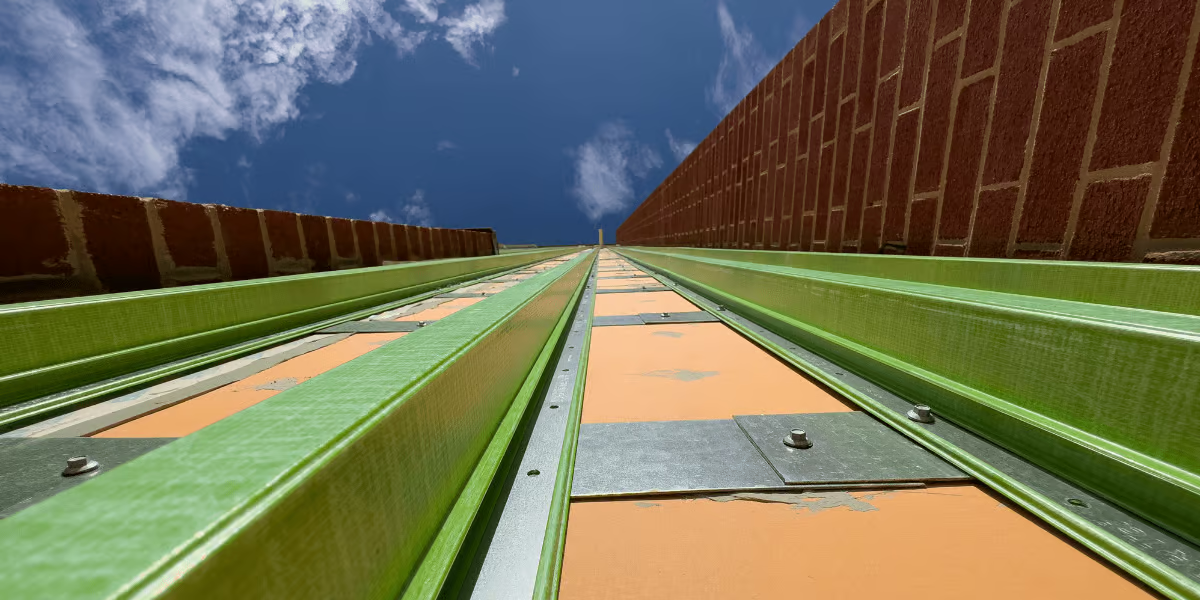

GreenGirt CMH uses a composite‑metal hybrid (CMH) Z‑girt—a composite fiberglass body for thermal performance with steel‑reinforced flanges for dependable load path and fastener retention. The design provides a permanent steel‑to‑steel fastener connection while eliminating through‑metal heat flow. ThermaLock insulation retention adds dual three‑point compression seals, eliminating the need for stick‑pins while supporting both air and moisture management.

- Eliminates thermal bridging. GreenGirt CMH’s ThermaLock eliminates thermal bridging as the insulation meets the technology’s three-point compression seals both above and below the insulation.

- High-performing durability. The composite fiberglass body carries wind and cladding loads at any spacing requirement, supported by the Z-girt’s steel flanges for increased support.

- Easy installation. Crews fasten it with normal self‑drilling screws as the fasteners connect with GreenGirt CMH’s steel flanges, solidifying a steel-to-steel permanent connection.

SMARTci

SMARTci pairs GreenGirt CMH Z-girts with custom‑profiled rigid insulation panels (factory routed to fit exactly with the depth of the Z-girt and the ThermaLock technology). The result is a continuous, uniform insulation layer with integrated ThermaLock insulation retention that maintains a smooth drainage plane and reduces jobsite cutting labor.

- Uninterrupted layer. A2P supplies custom-cut rigid board insulation that fits exactly to the Z-girt’s ThermaLock technology, eliminating the need for extra installation materials and keeps the continuous insulation layer uniform.

- Material flexibility. SMARTci is flexible with polyiso and XPS rigid board insulation, enabling a climate- and budget-appropriate selection without making sacrifices to the system’s performance.

- Efficient and easy installation. SMARTci installs up to 4x faster than certain conventional approaches, due to reduced site routing and simplified detailing.

5 Specification and Quality Assurance Tips

- Design to climate and program. PHIUS limits (space conditioning, infiltration, windows) are climate‑ and size‑specific; use PHIUS calculators/guidebook early to set envelope targets and attachments strategy.

- Practice mindful design tactics. A2P has CAD and Revit files on GreenGirt.com readily available for PHIUS submittals and to aid designers in easy implementation.

- Coordinate shop drawings. Call for CMH sub‑framing layout, Z-girt spacing, fastener schedules, and steel‑to‑steel fastening to the CMH flange; verify deflection, wind, and cladding loads with the engineer of record.

- Sequence for airtightness. Utilize blower-door testing to ensure the airtightness of buildings after all penetrations of the building envelope have been sealed to ensure compliance with energy efficiency standards.

- Installation quality. Enforce substrate prep and compression‑seal engagement per instructions; custom‑profiled insulation should be installed clean/dry with correct interlocks to maintain the drainage plane and seals.

Conclusion

For PHIUS‑aligned projects, the wall assembly must preserve continuous insulation effectiveness and airtightness. GreenGirt CMH provides a thermally efficient, structurally robust attachment strategy, and SMARTci integrates custom‑profiled rigid insulation to simplify delivery of high‑performance details in the field. Properly specified and tested, these systems can help teams meet PHIUS targets by eliminating thermal bridging, easing installation, and adhering to code and standards compliance.

Get Specs, Details, Drawings, & More for GreenGirt & SMARTci Systems

Grab all the necessary documents you need to specify GreenGirt and SMARTci systems for your next project designed to achieve PHIUS certification.

Download A2P’s Technical Documents

Need help designing a building envelope system that will help your project achieve PHIUS objectives? Our expert engineering team is available to assist your design concerns.

Related Resources:

A2P’s Comprehensive Thermal Performance Data

A2P’s Sustainability & Environmental Documentation

–

–

Frequently Asked Questions

How does GreenGirt CMH reduce thermal bridging at cladding attachments?

GreenGirt CMH uses a composite fiberglass body for thermal performance paired with steel-reinforced flanges for load path and fastener retention. That design enables a permanent steel-to-steel fastener connection while avoiding through-metal heat flow. Its ThermaLock insulation retention also uses dual three-point compression seals to support air/moisture management and eliminates thermal bridging.

What insulation materials can SMARTci use, and what’s the point of the custom-profiled boards?

SMARTci is compatible with polyiso and XPS rigid board insulation, letting teams choose by climate and budget without sacrificing system performance. A2P supplies custom-profiled (factory-routed) rigid insulation panels that fit the Z-girt depth and ThermaLock profile, creating a continuous, uniform insulation layer and helping maintain a smooth drainage plane while reducing jobsite cutting/routing.

When do you do blower-door testing for PHIUS/Passive House?

Sequencing airtightness verification with blower-door testing after all envelope penetrations have been sealed is best practice to confirm airtightness performance. For installation quality, we also recommend substrate prep, ensuring compression-seal engagement per instructions, and installing the custom-profiled insulation clean/dry with correct interlocks to maintain the drainage plane and seals.