I. Introduction to Girts

The Unsung Backbone of Modern Buildings

In the world of architectural design and construction, some elements, although critical, rarely grab the limelight. Girts are one such component. Integral to the structural integrity and façade support of buildings, girts play a pivotal role in modern construction, yet they often remain overlooked in discussions about building design.

A girt is essentially a structural beam or framework, typically made of steel, wood, or advanced composite materials, which is used to provide lateral or vertical support to the building’s wall panels or cladding. They are affixed to the building’s vertical columns or solid substrate and can also serve as a mounting point for various types of exterior wall systems. The function of girts is twofold: they not only help stabilize the structure against forces like wind and seismic activity but also contribute significantly to the building’s thermal performance when integrated with insulation systems.

The concept of using girts in construction is not new. Historical precedents can be traced back to the early days of large-scale construction, where timber girts were used in the framing of structures. However, with the advent of steel and, more recently, composite materials, the capabilities and functions of girts have evolved dramatically.

Modern construction demands efficiency, sustainability, and durability, and girts have adapted to meet these needs. For instance, the development of GreenGirt® Composite Metal Hybrid (CMHᵀᴹ) Z-girts, marks a significant advancement in this field. These products offer superior structural strength, thermal performance, and moisture resistance compared to traditional metal girts and composite-only girts, addressing many of the contemporary challenges faced in building design.

As we dive into the subject, this article aims to shed light on the various types of girts, their roles in building enclosures, the challenges in girt design, and the latest innovations that are shaping the future of construction. Through this exploration, we underscore the significance of girts and their evolving role in creating efficient, resilient, and sustainable buildings.

II. Types of Girts

Understanding the diversity in girt types is crucial. The choice of girt significantly impacts a building’s structural integrity and energy efficiency. Let’s explore the primary types of girts used in construction today.

Traditional Metal Girts

- Description: Traditional metal girts, often made of steel, are widely used due to their strength and durability. These girts are typically used to support wall cladding and can be seen in industrial buildings, warehouses, and commercial structures.

- Comparison: The primary advantage of metal girts is their high structural strength, which makes them suitable for supporting heavy loads. They are also known for their longevity and resistance to environmental factors. However, metal girts have a significant drawback in terms of thermal bridging. They can conduct heat, leading to energy inefficiencies in buildings. This thermal bridging can be a concern in hot and cold climates.

Composite-Only Girts

- Description: Composite-only girts are made exclusively from composite materials, devoid of any metal components.

- Comparison: Their primary advantage is their thermal performance, as they almost entirely eliminate thermal bridging. They are resistant to corrosion and offer significant weight savings over metal girts. Composite-only girts can present challenges in load-bearing capacity compared to metal or CMH girts.

Composite Metal Hybrid (CMH™) Girts

- Description: Composite Metal Hybrid (CMH™) girts represent a significant advancement in building technology. They combine the strength of metal with the thermal efficiency of composite materials.

- Comparison: Unlike traditional metal girts, CMH girts offer improved thermal performance by reducing thermal bridging without sacrificing structural integrity. This feature makes them an attractive option for energy-efficient building designs.

Wood and Other Material Girts

- Description: Wood girts have been used historically and are still relevant in residential and some commercial buildings.

- Comparison: While wood girts offer better thermal performance than metal, they are less durable and more susceptible to environmental damage like rot and insect infestation.

The evolution in girt technology reflects the construction industry’s response to changing demands for sustainability, energy efficiency, and architectural flexibility. While traditional metal girts continue to be used for their structural robustness, the rise of GreenGirt CMH girt technology demonstrates a shift toward solutions that balance structural strength with energy efficiency.

III. Role of Girts in Building Enclosures

In the architectural anatomy of a building, girts play a fundamental role in the structural and functional aspects of building enclosures. This section dives into how girts contribute to the overall effectiveness and efficiency of building enclosures, emphasizing their critical role in supporting cladding materials and impacting thermal performance.

Support Cladding Materials

- Girts provide the necessary structural support for attaching various types of cladding materials to a building’s exterior. Whether it’s metal panels, brick veneer, or composite cladding, girts ensure these materials are securely attached to the building structure.

- The placement, spacing, and material of girts are crucial in determining the load-bearing capacity and overall stability of the cladding system. They need to be aligned and installed correctly to distribute the loads imposed on the building’s exterior evenly, including wind loads and the weight of the cladding itself.

Impact on Thermal Efficiency and Insulation

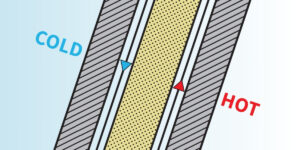

- One of the most significant roles of girts is in influencing a building’s thermal performance. In traditional metal girt systems, the phenomenon of thermal bridging can occur, where heat passes through the metal, leading to energy loss.

- Advanced systems, like GreenGirt CMH continuous insulation and SMARTci building enclosure systems, which utilize GreenGirt CMH girts, are designed to minimize or eliminate thermal bridging, thereby enhancing the building’s overall energy efficiency. By providing a more thermally efficient framework, these girts play a pivotal role in the building system.

- The integration of CMH girts with GreenGirt CMH continuous insulation and SMARTci building enclosure systems, further improves thermal performance. This synergy between girts and insulation is essential for achieving high energy efficiency in modern buildings.

Contribution to Moisture Management

- Girts also contribute to moisture management in building envelopes. Properly designed and installed systems help prevent water infiltration and allow for adequate drainage and ventilation of the cladding system.

- In areas where condensation is a concern, the use of girts and systems with thermal breaks or non-conductive materials can help mitigate moisture accumulation within the wall assembly.

Influence on Air Leakage

- Air leakage is a critical factor in the energy performance and indoor air quality of buildings. Girts play a role in creating airtight building envelopes, particularly when they are integrated with air barrier systems.

- The design and installation of girt systems must be coordinated with the air barrier system to ensure there are no gaps or weak points that could leak to air leakage.

The role of girts in building enclosures is multifaceted, extending beyond mere structural support to significantly influencing thermal efficiency, moisture management, and air tightness. As building technology evolves, the design and implementation of girt systems continue to adapt, aiming to meet the growing demands for energy-efficient and sustainable building practices.

IV. Challenges and Considerations in Girt Design

The design and implementation of girts present a series of challenges and considerations that are critical to the overall performance and longevity of the structure. This section explores these challenges, emphasizing how they influence the effectiveness of girt systems in various building applications.

Thermal Bridging and Its Impact on Energy Efficiency

- Issue: Thermal bridging occurs when a conductive material allows heat to bypass the insulating layer of a building, leading to energy loss. In traditional metal girt systems, this is a common problem.

- Impact: This phenomenon significantly affects a building’s energy efficiency and building health, leading to higher heating and cooling costs, potential moisture issues, and comfort due to inconsistent indoor temperatures.

- Mitigation Strategies: The use of advanced girt systems like GreenGirt CMH girts, which reduce thermal bridging and integration with continuous insulation systems, are effective ways to address this issue.

Structural Load Considerations and Durability

- Challenge: Girts must be designed to withstand various loads, including the weight of the cladding, wind loads, and seismic forces, without compromising the structural integrity of the building.

- Durability Concerns: The long-term performance of girts is also crucial. Factors like material fatigue, deformation under load, and wear over time need to be considered.

- Design Solutions: Engineering analysis and proper material selection are essential. For instance, steel girts offer high strength but might require treatments for enhanced durability, while CMH girts provide longevity with reduced maintenance.

Material Compatibility and Corrosion Resistance

- Compatibility Issues: Different materials in the building envelope can react with each other, especially in the presence of moisture or chemicals, leading to corrosion or material degradation.

- Corrosion Resistance: This is particularly important for metal girts, which can be susceptible to rust and corrosion in certain environments.

- Considerations: Selecting materials that are compatible with each other can mitigate these risks. Composite and CMH materials offer an alternative as they are resistant to corrosion.

Design Considerations for Different Building Types and Climates

- Building Types: The design of girts must be adapted to the specific requirements of the building type, whether it’s a commercial high-rise, industrial facility, or residential building.

- Climate Adaptation: The local climate plays a significant role in girt design. For example, areas with high humidity or coastal regions require corrosion-resistant materials, while colder climates necessitate better thermal performance to reduce heating costs.

In summary, the design of girt systems in building construction involves careful consideration of thermal performance, structural loads, material compatibility, and environmental factors. Overcoming these challenges is key to achieving efficient, durable, and sustainable buildings. As the industry evolves, innovations like GreenGirt CMH girts and SMARTci continuous insulation systems are playing a pivotal role in addressing these challenges, marking a significant advancement in building envelope technology.

V. Innovations and Advancements in Girt Technology

The construction industry is witnessing a dynamic shift in girt technology, driven by the goal of sustainability and energy efficiency. This section highlights the emerging trends, innovative applications, and the anticipated future of girt technology in the realm of construction.

Emerging Trends in Girt Materials and Design

- Advanced Materials: The shift toward Composite Metal Hybrid (CMH) girts exemplifies the industry’s move toward materials that offer better thermal performance and reduced environmental impact.

- Integrated Systems: There is a growing trend in integrating girt systems with other building components, such as continuous insulation and building envelope systems, for enhanced overall performance. GreenGirt CMH continuous insulation and SMARTci building enclosure systems are examples of this.

- Smart Design: The adoption of smart design principles, such as modular girt systems and prefabricated components, is on the rise. These approaches not only improve the efficiency of construction but also reduce waste.

The Future of Girt Technology in Sustainable and Energy-Efficient Construction

- Energy Efficiency: The ongoing pursuit of sustainability and energy efficiency will drive innovations in girt design, such as enhanced thermal breaks and integration with renewable energy systems.

- Regulatory Influence: As building codes and standards evolve to demand higher energy performance and sustainability, girt technologies will adapt accordingly, playing a key role in meeting these new requirements.

The evolution of girt technology is a testament to the construction industry’s commitment to innovation and improvement. With each advancement, girts are becoming more integral to creating buildings that are not only structurally sound but also energy-efficient and environmentally responsible.

VI. GreenGirt CMH: A Case Study in Advanced Girt Technology

GreenGirt CMH (composite metal hybrid) technology stands out as a pioneering solution in the realm of girt systems. This section provides a detailed overview of GreenGirt CMH Z-girts, its benefits in modern construction, and its role in addressing the challenges associated with girts.

Detailed Overview of GreenGirt CMH Technology

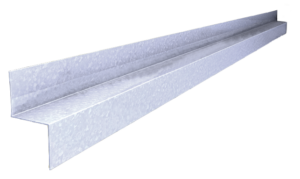

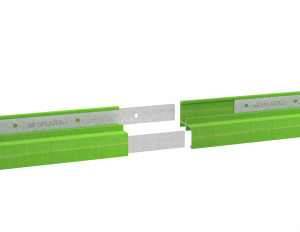

- Composite and Design: GreenGirt CMH Z-girt is a composite metal hybrid product that combines the strength of metal with the thermal efficiency of composite materials. The design integrates continuous metal inserts encased in a composite Z-profile, resulting in a girt that offers both structural integrity and thermal insulation.

- Installation and Compatibility: Designed for ease of installation, GreenGirt CMH Z-girts are compatible with a wide range of cladding, substrate, and insulation materials and can be used in various types of buildings. Its versatility makes it a suitable choice for both new construction and retrofit projects.

Benefits of GreenGirt CMH Z-Girts in Modern Construction

- Structural Performance: The standout feature of GreenGirt CMH Z-girts is its structural performance. GreenGirt CMH Z-girts do not compromise on structural strength. It provides robust support for cladding materials, ensuring the structural integrity of the building envelope under various loads and environmental conditions.

- Thermal Efficiency: Another standout feature of GreenGirt CMH Z-girts is its ability to eliminate thermal bridging, a common issue with traditional metal girts. By minimizing heat transfer through the building envelope, GreenGirt enhances the overall energy efficiency of buildings, leading to reduced heating and cooling costs.

- Sustainability: GreenGirt CMH is a step forward in sustainable construction practices. Its materials are chosen for their environmental friendliness and contribute to the building’s overall sustainability profile.

Addressing Challenges of Traditional Girts

- Thermal Bridging Mitigation: By integrating a composite Z-profile, GreenGirt CMH effectively interrupts the thermal bridge that is inherent in metal-only girt systems. This innovation plays a crucial role in enhancing the building’s thermal performance.

- Durability and Maintenance: The composite materials used in GreenGirt CMH Z-girts are resistant to corrosion and environmental degradation, which extends the lifespan of the girt system and reduces maintenance requirements compared to traditional metal girts.

- Flexibility in Design and Application: GreenGirt CMH’s design allows for greater flexibility in architectural applications, accommodating a wider range of cladding options and architectural systems and making it a versatile solution for various building types.

GreenGirt CMH Z-girt technology exemplifies the advancements in girt systems, offering a solution that effectively balances thermal efficiency, structural performance, and sustainability. It stands as a testament to the potential of modern building technologies to overcome traditional challenges and set new standards in construction practices.

VII. Conclusion: The Significance of Girts in Building Design and Efficiency

In conclusion, it’s evident that these structural components, though often understated, are fundamental to the integrity and efficiency of modern buildings. The journey through various girt types, their challenges, and the innovations in girt technology underscores their pivotal role in construction.

Summarizing the Key Roles and Benefits of Girts in Construction

- Girts serve as the critical link between a building’s primary structure and its exterior cladding, ensuring structural stability and support.

- Their influence extends beyond structural support to significantly impact a building’s thermal efficiency, moisture management, and overall energy performance.

- The adaptability of girts to different materials and architectural styles makes them an indispensable component in diverse construction projects.

The Ongoing Evolution and Importance of Advanced Girt Solutions like GreenGirt CMH

- The future of girt technology is aligned with the broader trends in the construction industry, focusing on sustainability, energy efficiency, and smart design.

- As building standards and codes continue to evolve, demanding higher performance and environmental responsibility, girt technologies will adapt and innovate to meet these new challenges.

- The increasing use of digital tools and prefabrication in construction suggests a future where girt systems are more integrated, efficient, and tailored to specific project needs.

In summary, the significance of girts in building design and efficiency cannot be overstated. From traditional metal girts to cutting-edge solutions like GreenGirt CMH, these components are crucial in shaping the buildings of today and tomorrow. As we look forward, the continuous innovation in girt technology will undoubtedly play a key role in advancing the construction industry toward more sustainable, efficient, and intelligent building designs.

© 2023 Advanced Architectural Products

Future Reading:

- Journal of Building Engineering: Offers insights into the latest advancements in building materials and technologies.

- Composite Panel Association: Provides detailed information about composite materials and their applications in the construction industry.

- Building Science Corporation: For insights on the principles of building science, particularly related to thermal and moisture management.

- National Institute of Building Sciences: Provides comprehensive resources on building envelope design and construction, including the role of girts.

- International Building Code (IBC): Provides guidelines on structural design and material specifications.

- Journal of Architectural Engineering: Offers research and case studies on advanced building materials and design considerations.

- American Society of Civil Engineers (ASCE): Offers resources on the latest engineering trends and innovations in construction materials.

- Green Building Solutions: GreenGirt CMH: Provides comprehensive information on GreenGirt® CMH™ technology and its applications.

- Construction Specifications Institute (CSI): Provides guidelines and standards for building materials, including girts.