Best practice: superior fastener retention

Explore advanced fastening techniques that enhance structural integrity in continuous insulation and building enclosure systems.

Best Practices

Fastener Retention

![]() Fastener retention is a critical component in the design and implementation of continuous insulation and building enclosure systems. It refers to the ability of fasteners to maintain their integrity and hold components securely over the lifespan of a building. This practice is crucial for preventing air and moisture infiltration, enhancing thermal performance, and ensuring overall structural stabilitry. Proper fastener retention is essential not only for meeting buidling codes but also for maximizing the efficiency and durability of the building envelope. As such, adopting systems followings best practices in fastener retention can lead to significant improvements in the performance and longevity of construction projects.

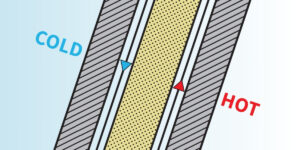

Fastener retention is a critical component in the design and implementation of continuous insulation and building enclosure systems. It refers to the ability of fasteners to maintain their integrity and hold components securely over the lifespan of a building. This practice is crucial for preventing air and moisture infiltration, enhancing thermal performance, and ensuring overall structural stabilitry. Proper fastener retention is essential not only for meeting buidling codes but also for maximizing the efficiency and durability of the building envelope. As such, adopting systems followings best practices in fastener retention can lead to significant improvements in the performance and longevity of construction projects.

Features

Pull-out strength

Continuous insulation and building enclosure systems must have sufficient fastener pull-out strength to resist forces like wind or thermal expansion, ensuring they remain securely anchored in their host material throughout the building’s lifespan.

ASTM D7332-B 7-Day Fastener Pull-Out Resistance Test

ASTM D7332-B is essential for ensuring FRP composites in continuous insulation and building enclosures meet safety and performance standards by testing fastener pull-through resistance under specific conditions. This compliance with best practices guarantees material durability and reliability.

Torque retention

It is crucial that fasteners maintain their initial torque settings over time, preventing loosening that could lead to structural weaknesses and increased air or water infiltration.No blind fastening

Avoiding blind fastening ensures every fastener is visible during installation, allowing for proper engagement and verification of correct seating to enhance structural integrity. This method also helps avoid unnecessary additional puncture holes, which can compromise the building envelope and reduce its overall effectiveness.

No cantilevered fastening

By eliminating cantilevered fastening, fasteners avoid bending forces, reducing the risk of mechanical failure and maintaining load-carrying capacity under stress.

How GreenGirt CMH and SMARTci Systems Meet and Exceed Fastener Retention Standards

The GreenGirt CMH and SMARTci systems set the standard for effective fastener retention, featuring components like the GreenGirt CMH Z-girts. This sub-framing includes continuous steel inserts renowned for their robust pull-out strength and superior torque retention. By employing precise and visible fastening techniques, these systems avoid the pitfalls of blind and cantilevered methods, thereby boosting the structural integrity and efficiency of continuous insulation and building enclosure systems. This careful and detailed engineered system significantly enhances durability, offering robust protection against environmental stresses.