“Badly installed insulation can be close to worthless.” – Passivhaus Trust [1]

What is Thermal Bypass?

As the demand for energy-efficient buildings grows, architects, designers, and builders increasingly focus on high-performance wall assemblies. While the emphasis has been on using high-performing insulation materials and reducing thermal bridging, the issue of thermal bypasses has often been overlooked.

Thermal bypasses arise from discrepancies within the wall assembly – including gaps, cracks, and unintended air movement – fundamentally undermining the thermal integrity of building enclosures. These irregularities can precipitate significant thermal degradation, culminating in heat loss and a consequent rise in energy demands for heating and cooling. Research indicates that the heat loss attributable to thermal bypass can lead to an additional heat loss of up to 93% [2].

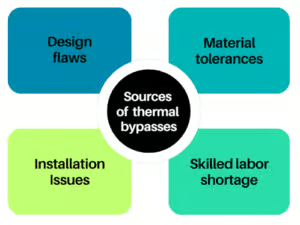

Graph illustrating the four primary sources of thermal bypasses

Sources of Thermal Bypass

Thermal bypass can occur due to various factors, including:

Design flaws

Design flaws are a significant source of thermal bypasses in building envelopes and can severely undermine the effectiveness of insulation. These flaws typically arise from inadequate or incorrect detailing of the building’s structural components, such as sub-framing sections and wall cavity geometries. When these elements are not precisely designed or executed, they can lead to the formation of gaps, cracks, and unintended air channels.

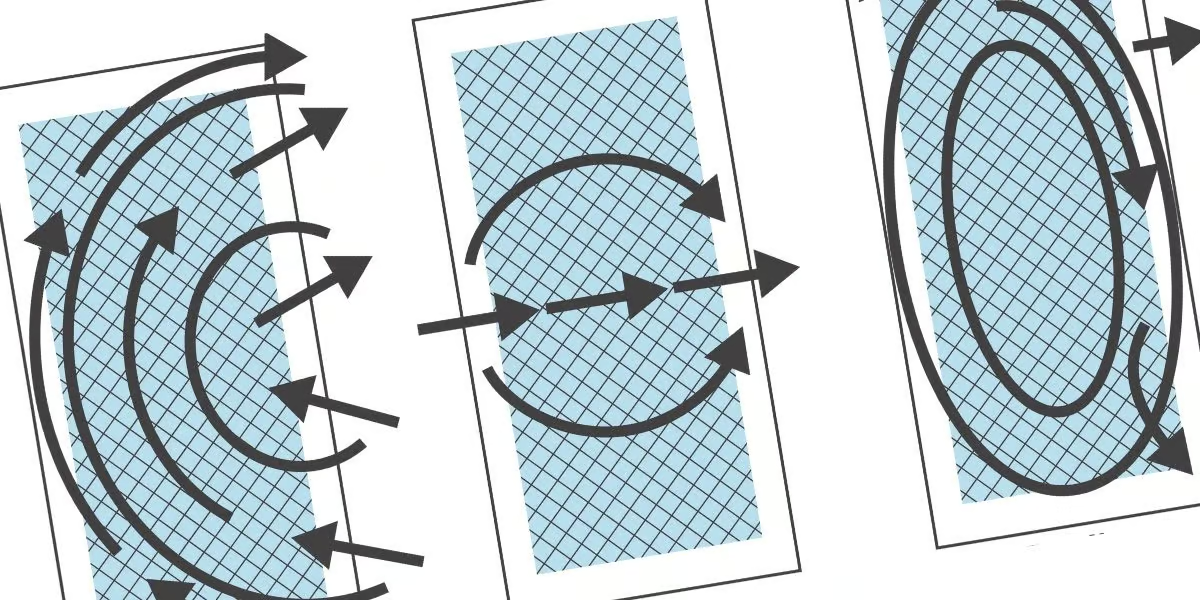

Video: Types of thermal bypass

These discrepancies allow air to circulate through or around the insulation layer rather than being effectively blocked. This unintended airflow not only reduces the insulation’s ability to maintain temperature but also compromises the overall energy efficiency of the building. Addressing these design flaws during the planning and design stages is crucial for ensuring a seamless and continuous insulation barrier that performs optimally.

Video: Air flow around insulation and through insulation

Video: Two examples of improper detailing of sub-framing sections and wall cavity geometries creating airflow gaps

Material tolerances

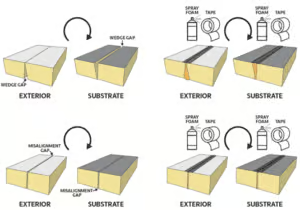

Material tolerances play a significant role as a source of thermal bypasses in building enclosures. Variations in the dimensions of wall components due to manufacturing tolerances can result in gaps and cracks when these materials are assembled on-site, compromising the continuity of the insulation layer. Specifically, rigid foam insulation panels are prone to variations in width, length, thickness, and squareness due to production processes. [1] For instance, according to manufacturing specifications, generic rigid board insulation may differ in length by up to ½ inch, in width by ¼ inch, in squareness by ¼ inch, and in thickness by 3/8 inch. These discrepancies can lead to significant challenges during installation, requiring meticulous attention to detail to ensure that gaps are properly sealed.

If these variations are not adequately addressed, they can create air channels that undermine the effectiveness of the insulation, allowing heat to escape or enter, thereby reducing the overall thermal efficiency of the building. This makes it imperative for installers to carefully inspect and adapt their techniques to mitigate these inherent material inconsistencies.

This example shows how joints between boards might look acceptable from above, yet there can be significant gaps that are not clearly visible and need to be filled.

Installation issues

Installation issues are a critical factor contributing to thermal bypass problems in building assemblies. During the installation process, installers must appropriately address any gaps and cracks caused by material variations or assembly methods. However, there can be a lack of diligent source material remediation by installers, who might not consistently recognize it is their responsibility to seal these imperfections. This oversight can occur for various reasons, including time constraints, lack of training, or insufficient attention to detail.

![Image 6: Example of wall cavity with gaps between and behind the insulation boards resulting in more heat loss than anticipated in the design. [1]](https://greengirt.com/wp-content/smush-avif/2024/05/Picture1-244x300.png.avif)

Example of wall cavity with gaps between and behind the insulation boards resulting in more heat loss than anticipated in the design. [1]

Skilled labor shortage

The shortage of skilled labor in the construction industry impacts the assembly of high-performance wall systems, contributing to potential thermal bypass issues. As demand for energy-efficient buildings increases, the need for trained installers who understand the complexities of modern insulation systems becomes crucial.

However, the prevailing labor shortage means that it is often challenging to find personnel with the necessary expertise and precision. This gap can cause improper installation, where installers may overlook or inadequately execute critical details such as sealing joints, fitting insulation correctly, and ensuring continuous coverage.

The Importance of Addressing Thermal Bypasses

“For a given thickness of insulation, a 7.5 mm gap could result in a 203% increase in heat loss; a 15mm gap could be a 520% increase.” – L. Alter [4]

Failing to address thermal bypasses can lead to severe consequences for building owners and occupants. Thermal bypasses can occur due to design flaws, such as gaps and cracks allowing air to flow around, through, or behind insulation, material tolerances and installation issues, and a shortage of skilled labor. As a result of thermal bypasses, a wall assembly’s actual thermal performance – or effective R-value – can be drastically reduced, often delivering less than half of what is intended by design [3].

This reduction in thermal performance directly impacts energy consumption, leading to higher utility bills. Since the building cannot maintain temperature as efficiently, heating and cooling systems must work harder and operate longer to compensate for the lost heat in winter and the gained heat in summer. This increases costs and accelerates wear and tear on HVAC systems, potentially leading to earlier-than-expected failures and replacements.

Moreover, the comfort of occupants is compromised. Inconsistent temperatures, drafts, and cold spots can become prevalent throughout the building, affecting the liability and satisfaction of its users. Additionally, the diminished effectiveness of insulation exacerbates environmental impacts by increasing the carbon footprint associated with excessive energy use.

Ultimately, ignoring thermal bypass issues undermines the overall sustainability of the building. Architects and builders must ensure proper insulation installation and functionality to meet building standards and regulations, while also upholding a commitment to energy efficiency and environmental stewardship.

2″ GreenGirt CMH Z-Girts that eliminate thermal bypass with custom-profiled insulation

Conclusion

Thermal bypasses are a critical issue in building enclosures that can significantly undermine the thermal performance of wall assemblies. Understanding the sources of thermal bypasses—such as design flaws, material tolerances, installation errors, and labor shortages—helps stakeholders tackle these challenges. This approach enables designers, builders, and building owners to deliver high-performance, energy-efficient buildings.

Investing in comprehensive solutions that address these various challenges is essential to ensuring that building owners and occupants benefit from the full potential of a well-designed and properly executed building enclosure. This commitment not only enhances the sustainability of the building but also ensures long-term savings and improved conditions for occupants.

Optimal Solution: SMARTci® Building Enclosure System

Comprehensive Approach to Eliminating Thermal Bypass

A comprehensive approach addresses design flaws, material tolerances, and installation and labor challenges. This method effectively mitigates thermal bypasses. The SMARTci building enclosure system offers a high-performance, easy-to-install solution that addresses all four common sources of thermal bypasses.

Precision Engineering for Seamless Installation

This system features factory custom-profiled insulation panels and composite interface components with a 0.005-inch tolerance. This ensures a precise fit and eliminates gaps. Each insulation panel in the SMARTci system forms compression seals on all four sides. The structural interfaces provide at least three additional compression seals on each side. This precision engineering and robust sealing method eliminate gaps within the system. It prevents air circulation and thermal bypasses, eliminating the need for tape or caulk.

Furthermore, the SMARTci system simplifies installation, significantly reducing the potential for workmanship-related issues that could lead to thermal bypasses. The precise tolerances and simplified installation process minimize the risk of component size variations and installation errors. This ensures the system is inherently air- and water-tight once installed. Installers can complete the SMARTci system 2-4 times faster than traditional insulation systems. This makes it an efficient and reliable solution.

Complete Solution for Thermal Bypass Prevention

The SMARTci® system addresses four critical areas: design, material tolerances, installation, and labor skill level. This comprehensive approach effectively prevents thermal bypasses in building enclosures.

Talk to A2P’s Building Envelope Experts

Have a question about thermal bypass? Send us a message and we will connect you with your A2P territory representative to guide you in selecting the best continuous insulation system to meet your project’s performance requirements while eliminating thermal bypass.

Speak with Your A2P Territory Representative

Related Resources:

A2P’s Thermally-Efficient Solutions for Walls, Roofs, & Windows

A2P’s Comprehensive Thermal Performance Data

References:

[1] Passivhaus Trust. (2017). Passivhaus Insulation: Good practice guide to achieving insulation continuity.

[2] Trethowen, H. A. (1991). Sensitivity of insulated wall and ceiling cavities to workmanship. Journal of Thermal Insulation, 15(2), 172-179.

[3] Lecompte, J. (1990). The influence of natural convection on the thermal quality of insulated cavity construction. Building Research and Practice, 6(6), 349-354.

[4] Alter, L. (2022, October 7). Thermal bypass is another thing for builders to worry about. Treehugger Voices. https://www.treehugger.com/thermal-bypass-builders-5194768

–

–

Frequently Asked Questions

What is thermal bypass?

Thermal bypass is heat loss (or heat gain) caused by gaps, cracks, and unintended air movement inside a wall assembly, where air circulates around, through, or behind insulation instead of being blocked. It can severely degrade building envelope performance.

What causes thermal bypass in wall insulation?

The four main causes of thermal bypass are: design flaws, material tolerances, installation issues, and skilled labor shortage.

How does SMARTci stop thermal bypass and air leakage?

SMARTci prevents thermal bypass by using precision-fit, factory custom-profiled insulation panels and composite interface components manufactured to a 0.005-inch tolerance, which is intended to eliminate gaps. Each panel forms compression seals on all four sides, and the structural interfaces add at least three additional compression seals per side, creating a robust seal that prevents air circulation, so it eliminates the need for tape or caulk.